The Salata Building in Qatar ... striking aesthetics.

The Salata Building in Qatar ... striking aesthetics.

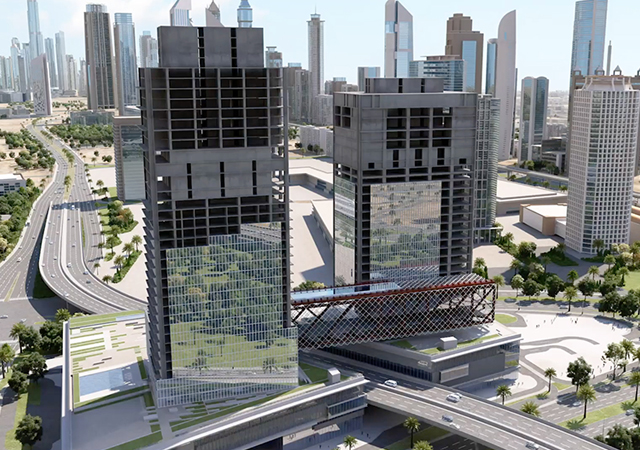

Neolith by TheSize, a brand of all-natural, premium sintered compact surfaces, has been used to clad the new Salata Building in the heart of Doha, Qatar.

Designed by Elias Bou Raffoul from E-Square Architects, this spectacular construction stands out for its striking geometrical aesthetics.

“The irregular lines embody the contrast and the relationship between a full and empty space, between an inner and outer space, and the negative and positive, creating the different structures of the building,” Raffoul explains.

Neolith by TheSize was specified for its lightweight and large slab formats that provide a high-performance solution and reduce installation time.

The ventilated façade system can contribute to a building’s thermal efficiency in terms of energy consumption, with savings reaching up to 40 per cent, says a spokesman for TheSize, its Spanish manufacturer.

“Furthermore, the cladding offers insulation since it is resistant to ultraviolet (UV) exposure and temperature changes – factors that are crucial especially in a region where the climate can reach 50 deg C,” he stresses.

Raffoul used Neolith Avorio and Nero from the Colorfeel Collection, as well as Rojo Qatar, a colour developed exclusively for the project, to create a unique building that is durable, versatile and sustainable.

Headquartered in Castellón, Spain, TheSize was founded in 2009 with the objective of creating a new material category suitable for exterior and interior construction such as for kitchen and bath countertops, furnishings, flooring and facades.

The company launched the Neolith brand in 2011 as a high-end compact surface with revolutionary physical and technical features. A term meaning “new stone”, Neolith combines high-quality natural raw materials with state-of-the-art technology to create a high-tech slab.

Neolith is a pioneer brand, providing a high-tech, versatile architectural solution with avant-garde properties.

“The Neolith brand is the outcome of the latest research and development processes in the industry. The product is 100 per cent natural, composed of raw material – clays, feldspar, silica and natural mineral oxides, and is recyclable,” says the spokesman.

He says Neolith has near-zero porosity, making the product hygienic, stain-resistant, easy to clean and impervious to chemicals.

“The product is also wear-, scratch- and heat resistant and its colours – being a natural base – do not vary when exposed to UV rays. Additionally, the product is lightweight and easy to install, making Neolith suitable for virtually every indoor and outdoor surface.”

The product is created through the company’s proprietary sinterisation technology, exposing minerals and other raw materials to extremely high pressure and temperature (over 1,200 deg C), resembling the way natural stone forms over thousands of years, in just hours. The process gives the product outstanding physical and mechanical properties in terms of compaction, resistance and durability, according to the spokesman.

The various style collections are a result of Neolith’s innovative Digital Design (NDD) decoration technique. “This system has revolutionised Neolith patterns and is pushing the boundaries of what colours and textures are possible from compact surfaces,” the spokesman concludes.

.jpg)

.jpg)

.jpg)

.jpg)