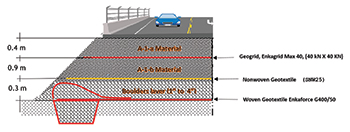

Figure 1: Bonar Natpet’s design involves the use of three layers of geosynthetic material.

Figure 1: Bonar Natpet’s design involves the use of three layers of geosynthetic material.

Bonar Natpet, a leading geosynthetics producer and supplier in the Middle East, has offered its expertise on a road project being constructed in the Special Economic Zone at Duqm (Sezad) in Oman. Part of the road will be constructed over Sabkha soil, which needs to be stabilised.

The National Route 32 (NR 32) at Duqm is a six-lane dual carriageway, approximately 16 km long, and includes bridges, service roads, roundabouts, tie-in roads to existing or ongoing construction roads, culvert crossings, utilities, street lighting, drainage structures and ancillary works.

As per the client’s requirements, Bonar Natpet says it proposed a design (Figure 1) to stabilise the Sabkha soil using a geosynthetics material that would help to improve the embankment performance and durability during the service life of the road. It comprises three layers of geosynthetic material: the basal reinforcement layer, woven geotextile (Enka-Force G400/50), a layer of non-woven geotextile (SNW25), and finally a layer of geogrid (Enkagrid Max 40).

Enkaforce G400/50 will help in the safe and effective construction of the embankment. The potential tensile strength mobilized within the Enka-Force reinforcement will be about 7.0 kn/m. However, the SNW25 non-woven geotextile layer will act as a filter for the soil above, thus preventing the erosion of the backfilling and any consequent settlement, according to Bonar Natpet.

|

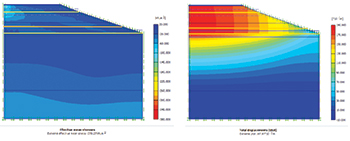

Figure 2: Effective stress and settlement (right) due to backfilling and traffic loading. |

The upper geogrid, Enkagrid Max 40, will increase the stability of the above soil and the resilient modulus, it adds.

The Plaxis 2D finite element software package was used to run the analysis. Figure 2 shows the total effective stress and the settlement of the embankment.

Elaborating on the properties of these three layers, the company says the high-modulus multifilament yarns used in the production of Enka-Force offer excellent creep characteristics, making it the perfect choice for use in soil reinforcement applications. The range has been specifically designed to exhibit high strength at low elongation.

Typical areas of application include reinforced soil walls, embankments and load transfer platforms. During use, the stresses are transferred into the plane of the reinforcement by friction between the soil and the soil reinforcement fabric. The product’s hydraulic properties make it suitable for use in most soils and granular fills.

Enka-Force woven geotextiles can be used in the construction of vertical walls, steep slopes and embankments over soft ground. As soil is very strong in compression but weak in tension, Enka-Force geotextiles will provide tensile resistance within the soil mass.

Meanwhile, SNW (Superior Nonwoven Geotextile) is a needle-punched, lightly thermally-bonded geotextile designed to offer outstanding performance at minimum weight. The SNW range offers superior puncture resistance when compared with most other needle-punched nonwoven products of comparable weight, says Bonar Natpet. Its principal functions are protection, separation and filtration.

Through the optimum combination of polymer and production technology, the SNW range is the perfect choice for use in the protection of impermeable membranes in landfill and reservoir construction as well as for coastal protection from erosion below rock and concrete defences.

Finally, Enkagrid Max is a high-performance and cost-effective biaxial geogrid used worldwide in civil engineering projects for sub-base stabilisation, designed for achieving maximum bearing capacity and shear resistance. The range exhibits an optimum interaction with all granular soil types, making it ideal for sub-base stabilisation. It is typically used for construction of roads or platforms on weak soils where it delivers extra stiffness and prevents differential settlements, thus prolonging the life expectancy of the project.

Bonar Natpet is a leading producer of polypropylene in the GCC that exports to countries across the world. It manufactures products of the highest quality that have been used in the regional market for over 15 years.

It has a geotextile production plant in Yanbu, Saudi Arabia, and countrywide offices in Jeddah, Dammam, Riyadh, in addition to one in Dubai (UAE).

_0001.jpg)

.jpg)

.jpg)

.jpg)