Royal Albert Hall in London.

Royal Albert Hall in London.

Pipe systems in buildings are like veins in our bodies – of vital importance and mostly invisible. They transport and distribute drinking water, collect wastewater, deliver energy for heating and cooling, cables and much more, providing a high level comfort in residential and institutional buildings.

Polyolefin thermoplastic pipes have an excellent track record for more than 60 years and offer many advantages as opposed to pipes made from ‘traditional’ materials, such as long service life, light weight (ease of handling and transportation), good chemical resistance to aggressive media and soils, corrosion resistance, excellent balance of stiffness and impact resistance, high creep strength, insusceptible to deposits and encrustations, low noise emission and can be joined using a wide range of techniques.

What is polybutene?

In many ways PB-1 (Polybutene-1) is like bamboo – flexible and lightweight. While being a very flexible material, it is also very strong and offers excellent temperature resistance, when compared to many alternative pipe materials – and belongs to the same polymer family as PE (polyethylene) and PP (polypropylene). PB-1 is not a new material – pipe systems of PB-1 have been in use for more than 40 years – and is known to be the most technically advanced material for pressure pipe systems.

|

|

PB-1 was selected because of its flexibility, allowing to smoothly follow the unique shape of the building. |

Strength & SDR classes

Undoubtedly, the most important property of plastic pipes is their hydrostatic strength behaviour under continuous internal pressures which, in the end, is what determines the service life expectancy of the pipe.

The well-known PE 100 class material has a MRS 10 with a design strength of 10 MPa for 50 years at 20 degrees C. Some PP-RCT pipe grades of the latest generation offer a MRS (minimum required strength) class of 12.5, which means 12.5 MPa design strength.

Lyondellbasell, one of the world’s largest raw material suppliers for the manufacture of pressureless and pressurised thermoplastic pipes, offers PB-1 – for example, Akoalit PB 4267 Grey, which is classified as MRS 14, which means 14 MPa.

Plastic pipes are often classified with a standard dimension ratio, or SDR, which is simply the ratio of the pipe outside diameter ‘d’ and the wall thickness ‘s’.

For every diameter and SDR class, the wall thickness can be calculated and vice versa. By knowing the diameter and the wall thickness, the inside diameter can be calculated as well as the inside cross-section area of the pipe.

SDR 13.6, SDR 11, 9, 7.4 and SDR 6 are fixed in the standards besides several other classes and apply to all plastic pipe materials such as PE, PP, PE-X and PB-1.

The SDR classification facilitates the capability comparison of different plastic pipe materials used in pipe systems.

|

|

BD Bacata building ... allowed for a one-to-one comparison of the ease of installation. |

Piping system design

The ISO 10508 standard for “Plastic piping System for Hot and Cold Water installations – Guidance for the Classification and Design” gives different application classes.

Polypropylene (PP-H, PP-R, PP-RCT), polyethylene (PE-X, PE-RT) and polybutene (PB-1) are the plastic materials for hot and cold water installations. Based on the applicable standards, piping systems can be calculated for each material.

In Figure 1, different plastic pipes with a service pressure of 8 bar and a diameter of 50 mm were chosen. The results are clear: PB-1 is the material with the highest SDR class, offering the highest cross-section area and has the lowest weight per meter pipe.

Figure 2 shows that pipes made from PB-1 offer 63 per cent more inside cross-section area compared to those made from PP-H/PP-R when considering the same operating pressure and the same outside diameter.The reduction of the wall thickness means a lower material consumption per meter pipe. PB-1 offers a 48 per cent lower weight than a comparable pipe made from PP-H/PP-R.

The much bigger inside cross-section area has a huge influence on running a pipe system as illustrated in Figure 3.

For a comparison, at 8 bar, the output of a pipe system made out of PP-H/PP-R is set at 100 per cent. PE-X/PE-RT/PP-RCT pipes have a 50 per cent higher output and PB-1 pipes have a 92 per cent higher output compared to the PP-H/PP-R pipes. When running the three different pipe systems at the same output, a pressure loss reduction of 69 per cent with PB-1 versus PE-RT is observed.

A higher SDR class means a higher output or a substantially lower energy consumption for operating the pipe system. The energy costs to run a pipe system for the calculated service time (typically 50 years) are much higher than the installation costs. This aspect should not be ignored.

Water hammer

Just before a pipe valve is closed, the mass of water in front of such valve is still moving. This sudden blockage causes a high pressure build-up, which results in a shock wave, so-called water hammer.

In buildings, water hammer may occur whenever a dishwasher, washing machine or toilet flushing reservoir suddenly shuts off the water flow. The result is heard as a loud bang. Besides these noises, water hammer can cause pipelines to break if the shock wave pressures become too high.

The combination of the lower flow rate and the lower propagation rate of the pressure wave will lead to a reduction of the water hammer of 76 per cent in PB-1 pipes when compared to pipe systems made from PP-H or PP-R materials (Figure 4). Note that the propagation rate is dependent on the overall pipe stiffness; a result of the pipe’s wall thickness and the material’s flexural modulus.

Sound dampening

A high elasticity and a low specific density of the pipe material in combination with a low wall thickness (high SDR class) will yield good dampening properties. PB-1 pipes are, by far, the best in class, absorbing pressure and sound waves and eliminating the annoying noises associated with piping systems in buildings.

Jointing techniques

PB-1 is a versatile material when it comes to jointing and installation, offering all types of connections like push-fit fittings, butt fusion, socket fusion, electrofusion as well as mechanical fittings.

Royal Albert Hall, London

At London’s Royal Albert Hall, one of the world’s greatest concert venues, the corroded steel pipe system was completely replaced by a PB-1 pipe system contracted by Georg Fischer Piping Systems in Switzerland.

Besides a longer life span when compared to steel, PB-1 was selected because of its flexibility, allowing to smoothly follow the unique shape of the building and thus reducing the total installation time.

In use, the PB-1 pipe system yielded substantial energy savings compared to the former steel pipe system. However, probably one of the most crucial aspects for a venue like the Royal Albert Hall was the much appreciated reduction of noise emissions by water hammer and the absence of ticking pipes when heating up or cooling down.

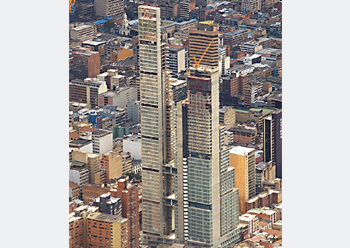

Hi-rise building, Colombia

BD Bacata, a 67-storey residential and commercial skyscraper in Bogota, Colombia, spread over 1 million sq m consists of two towers. For the South tower, PB-1 was specified for the hot and cold water supplies, using pipes ranging from 15 to 125 mm diameter and was contracted by Nueva Terrain in Spain. For the North tower, a conventional thermoplastic material was used, applying traditional installation techniques.

This allowed for a one-to-one comparison of the ease of installation, which was substantially quicker with PB-1, thanks to the flexibility of PB-1 pipes, while reducing the number of joints and fittings.

In addition, the unmatched water hammer absorption characteristics of PB-1 create a quieter and more pleasant living and working environment as well as a more durable pipe infrastructure within the building.

Summary

The use of PB-1 for pressure pipe systems offers:

• Substantial material saving opportunities, while increasing the capacity of the system;

• Opportunities for reduced integral installation cost and cost in operation;

• A versatile material that significantly reduces the negative effects of water hammer while positively affecting the lifetime of the pipe system.

* Lyondellbasell is one of the world’s largest raw material suppliers for the manufacture of pressureless and pressurised thermoplastic pipes. Comprehensive information on PB-1 pressure pipes is available through www.pbpsa.com. The PolyButene Piping Systems Association is an international association of leading companies who are committed to the use of PB-1 for the manufacture of pressure pipe systems.

_0001.jpg)

.jpg)

.jpg)

.jpg)