Inspection at a Mideast steel mill.

Inspection at a Mideast steel mill.

UK-based Cares elaborates on its established approach to product certification that assures quality of constructional steels, providing the public and private sectors the confidence that their assets will be structurally safe and sustainable.

Construction project teams face a clamour of demands and standards to successfully complete a project. Not only must quality and costs be controlled tightly on site, but they must be kept in check right up the supply chain too.

Careful management of supply and site operation will help meet a client’s requirements. It is well known that reinforcing steel, vital in construction, comes from a complex, national and international mix of companies involved in its production, processing and delivery.

It is an accepted best practice to use steel reinforcement products that are assessed using UKAS (United Kingdom Accreditation Service)-accredited conformity assessment services whenever this is an option. At the heart of such practices is Cares.

Cares directors and auditors are on site and upstream, in the UK and overseas across 40 countries. They know the pressures on site to deliver safely on time and on budget. They also know the risks that threaten success; but they offer the means to mitigate the risk too.

Its team has a proven track record with over 30 years’ experience of devising and running certification schemes to meet the standards required.

“Cares is an independent, not-for-profit certification body providing confidence to the users, purchasers and specifiers of constructional steels through regulation, testing and inspection,” says Lee Brankley, Cares acting chief executive officer. “Clients and specifiers can specify Cares-approved reinforcement manufacturers and fabricators having confidence that the product will comply with the relevant reinforcement standard without the need for costly, on-site testing.”

In the UK, Cares product certification is specified by the UK Specification for Highways Works, County Councils, the National Building Specification, Network Rail and the National Structural Concrete Specification (NSCS).

Cares product conformity certification offers rigorous management control of quality, consistency of technical quality, industry-developed rules and standards, and auditing by experienced professionals from the industry.

Distinctive benefits thus arise as the Cares-approved supplier can demonstrate consistent product quality, a competitive edge, improved systems, marketing opportunities and external recognition. Specifying the Cares Product Certification Scheme is the mark of quality, competence and the highest level of assurance.

|

|

Cares ... quality assured. |

Assuring quality

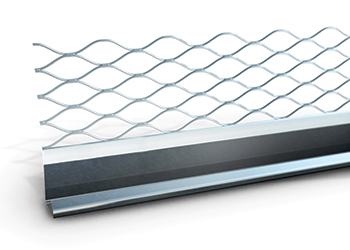

The scheme covers the entire supply chain for reinforcing steel. It’s open to all manufacturers and processors who can show that they can meet the required standards, no matter where they are in the world. In the main, the products covered by the Cares Steel for the Reinforcement of Concrete Scheme are bar and coil, fabric, cut and bent reinforcement, welding and prefabrication of reinforcing steel.

An applicant company is visited and assessed for product compliance (to BS4449) and quality management system compliance (to ISO 9001). Once approved, it is subject to at least two audits per year, with independent product testing at UKAS-accredited laboratories.

Cares offers the only construction product certification scheme accredited by UKAS to BS 8902.

All steel from Cares-approved companies is labelled to ensure traceability. All approved reinforcing steel is marked. Cares-approved companies provide a statement of product test results if required and must have a rigorous customer complaint process.

Cares independent chairman of the board, Professor Les Clark, declares: “I am delighted with our increasing growth and impact in the market. In 2014, Cares saw the further development of the Environmental Product Declaration model, and our Breeam (Building Research Establishment Environmental Assessment Methodology) recognition was re-confirmed in 2014 under the latest Breeam UK New Construction 2014 green building rating system. This excellent news is a great credit to Cares and my team here.”

Assured sustainability data

Accompanying the product conformity scheme, the Sustainable Constructional Steel Scheme provides data on sustainability performance of approved firms. Also, to achieve sustainability certification, the product must have a relevant Environmental Product Declaration (EPD) every three years, so the design phase is increasingly important to allow strong performance against the six key indicators in an EPD. This approach facilitates the publication of third party verified EPDs that meet the requirements of steel producers and construction clients.

Commenting on the Cares schemes relevance in terms of Abu Dhabi’s Estidama’s sustainability programme, Cares general manager Ayhan Tugrul says: “You need not worry about missing Estidama materials section points if you specify Cares. And as Estidama pushes further, you can expect Cares to deliver on the new requirements.”

Highlighting the need for such schemes, Sarah Kaethner, structural associate director at Arup, a global firm of consulting engineers, says: “We have been impressed by the enthusiasm of the construction industry to take on responsible sourcing. Sector schemes were needed to make this a reality and the Cares scheme meets this need.”

Robust governance

Cares is governed by its board and advised by its Policy Advisory Committee (PAC), whch is at the core of its work following a restructuring in 2012. The PAC comprises organisations representing specifiers, contractors, users and manufacturers. These include the Association for Consultancy and Engineering, Heathrow Airport, British Association for Reinforcement, Civil Engineering Contractors Association, Construct, UK Contractors Group, Highways England, Institution of Structural Engineers, Post-tensioning Association, UK Steel Association, Office for Nuclear Regulation (ONR/HSE), Rail Safety and Standards Board (RSSB), and Stainless Steel Specialist Expert. PAC members are not Cares’ company directors.

Cares is also accredited by UKAS to ISO Guide 65 (product certification) and ISO 17021 (management systems certification). Crucial for such accreditation are impartiality, auditor competence and client confidentiality. Cares is a Notified Body in accordance with the Construction Products Regulation and works to rigorous rules on dealing with feedback or complaints.

|

|

The only construction product certification scheme accredited by UKAS to BS 8902. |

Responsiveness

When it comes to appeals, inquiries or complaints, Cares operates a professional approach in accordance with UKAS accreditation requirements. Guided by its rules on client confidentiality and impartiality, it has to follow due process to ascertain facts. Cares will conduct detailed inquiries and re-audit or impose other sanctions as necessary.

Brankley is keen to stress that all Cares-approved firms implement a complaints procedure: “Any users with a concern about a Cares-approved manufacturer, trader or fabricator can take it up directly with them initially. If it cannot be resolved satisfactorily, they should come to Cares. Any complaints, especially those regarding product quality, are thoroughly investigated and always based on the evidence available. The Cares complaints procedure is freely available from the Cares website.”

Developments

High level discussions are reverberating around the industry on the sustainability policy or the 2025 Industrial Strategy for Construction. Focusing on practical measures, Cares is this month (June) set to launch the new product conformity certification scheme for the manufacture and supply of reinforcing steel for use in the nuclear power sector and other mega projects. It will apply to organisations possessing existing valid Cares certificates on quality management, product conformity, sustainability and occupational health and safety. Approved firms will also use the Cares Cloud to transfer product test and traceability data across the whole supply chain.

Cares is participating is and is a Gold Sponsor of the UK Rail Conference, being held from June 23-24, at Victoria Park Plaza, London, the UK.

_0001.jpg)

.jpg)

.jpg)

.jpg)