Application ... the new Seamtek 36.

Application ... the new Seamtek 36.

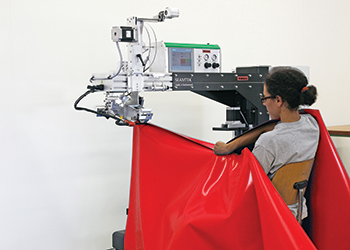

Leister Technologies, a global market leader in the areas of plastic welding and industrial hot air applications, has launched the new Seamtek 36, which is an extremely versatile and reliable machine for the welding of technical textile and industrial fabrics.

Technical textile and industrial fabrics are used in the manufacturing and welding of products such as flexible ventilation ducts, filters and tubes for mines and factories, tents, sunshades, water bladders, temporary floating barriers (used to contain an oil spill), pool liners and promotional billboards, signs and banners.

The digital technology of the new welding machine ensures perfectly welded, long-lasting seams, according to BMC Gulf Trading, Leister’s sales and service partner in the UAE.

“From start to finish, each step of the seaming process is digitally controlled for optimal accuracy and seam integrity,” says Fabian Beerman, division manager at BMC Gulf.

The Seamtek 36 boasts high flexibility as its modular construction allows the user to quickly adjust the machine from hot-air welding to tape welding in minutes or less. It is also versatile, being suitable for several types of welds such as overlaps, butt joints, hems of all forms, tapes and prayer welds.

The welding machine has an upper wheel speed differential to correct registration errors, prevent wrinkling and enable quality sealing around curves; a test strip that helps pinpoint the perfect machine parameters; and very strong and smooth step motors.

This apart, Seamtek 36 offers easy access to and view of the welding process; and a multilingual user interface with touchscreen control.

_0001.jpg)

.jpg)

.jpg)

.jpg)