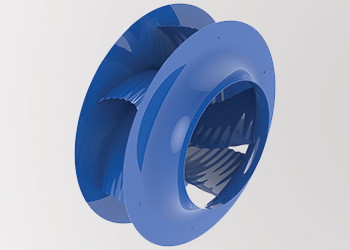

Ziehl-Abegg is applying knowledge on bionics gained from humpback whales to the new ZAbluefin radial fan.

Ziehl-Abegg is applying knowledge on bionics gained from humpback whales to the new ZAbluefin radial fan.

Ziehl-Abegg of Germany has drawn inspiration from nature, more specifically from the humpback whale, to design its latest radial fans that reduce energy consumption and offer quieter running for central air-handling units.

Called ZAbluefin, these latest generation fans have benefited from knowledge gained in the field of bionics.

Board chairman of Ziehl-Abegg Peter Fenkl says: “The idea for this new latest generation of radial fans comes from the humpback whale, allowing for energy savings of up to 10 per cent. Our engineers have, therefore, clearly underlined their role in the forefront of bionics and as a leader in fan technology.”

He says Ziehl-Abegg delivers peak efficiency in excess of 70 per cent in its radial fans. Every approach must, therefore, be used to optimise this. The angle at which the airflow meets the fan blade depends on the flow volume.

Drawing a comparison with the whale, Fenkl says the mammal has to overcome similar challenges when swimming in the sea. The movement of the fins causes the angle to constantly change. If its pectoral fins were to be at too steep an angle to the counter-flow, this would produce a lot of turbulence as the water passes over them.

“The characteristic features of excessive turbulence are high flow losses and noise,” says Dr Walter Angelis, technical manager for ventilation systems at Ziehl-Abegg.

Over millennia the humpback whale has optimised the design of its fins. For example, the leading edge of the whale’s fins contains golfball-sized bumps (technically called tubercles). With its long pectoral fins, a whale weighing 25 to 30 tonnes can swim very quickly and with great agility. “We have recreated this on the leading edge of the fan blade and implemented it as an undulating profile,” explains Angelis.

The flow engineers have also taken a close look at the whale’s rear fin, the “fluke”. The V-shaped contour of the rear section of the wing delays potential flow breaks – enabling the fan to be used for numerous different pressure ranges.

“We have also fitted a torsion to the fan blade,” adds Angelis. “This creates an optimum angle of flow over the entire span. It’s not just the jagged trailing edges that make the impeller run quieter; the undulating design of the blade surfaces reduces the noise level.”

Experts at Ziehl-Abegg spent about two years on the new centrifugal impeller for air-handling units and industrial ventilation. A bionic profile has proven very effective in terms of efficiency and low-noise.

“With the bionic profile blades, unlike currently commercially available hollow profiled blades, there are no gaps into which dirt or condensation can penetrate, leading not only to corrosion but also creating an imbalance. The steel is, therefore, pressed into a corrugated shape using a 600-tonne press, creating the bionic profile. This gives us additional strength and enables us to optimise the weight,” emphasises Angelis. “Less weight protects the bearings in the motor.”

The ZAbluefin fans come in sizes starting from 710 mm. The new radial impeller possesses characteristics from two completely different approaches to the field of bionics: both in terms of aerodynamics (ornithology) as well as hydrodynamics (marine biology). The trailing edges of the ventilator blades recreate the flight of an owl, for example.

The serrated trailing edges on fans have since become one of Ziehl-Abegg’s trademarks. On the new fan, however, the edges have been slightly modified and softened.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)