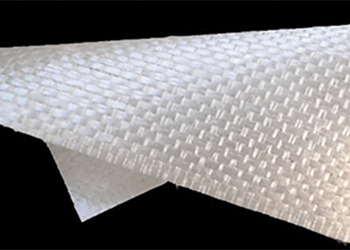

Rovicut ... glassfibre reinforcement.

Rovicut ... glassfibre reinforcement.

Chomarat has recently unveiled its new glassfibre reinforcement Rovicut, which stretches to hug the curves of pipes and conduits that need to be rehabilitated, without sacrificing mechanical performance.

Rovicut, the first stretchable woven reinforcement for renovating cured-in-place pipes (CIPP), come with advantages such as reduced weight and thickness for faster, more cost-effective installations, says a spokesman for the international textile group, which is headquartered in France.

Chomarat developed Rovicut in collaboration with Reline Europe, a leading manufacturer of sleeves for the in-situ repair of pipes.

“Rovicut is unique in the market, because the sleeve thickness is optimised to make it more lightweight, thus making it easier to handle and install, with faster UV (ultraviolet) cure. So there is a considerable economic advantage,” says Chomarat sales manager Marlene Berthouze.

Trenchless technology using CIPP consists of manufacturing sleeves from glassfibre reinforcements, coating them with resin, installing them inside a damaged pipe system and curing them under ultraviolet light, he explains. The pipes are renovated without opening up a trench, so there is no noise disturbance or dirt, and road traffic is not disturbed.

Rovicut was designed specifically for Reline’s new Alphaliner 1800 line dedicated to large-diameter pipes. Because it is stretchable, the reinforcement takes the exact shape of the worn pipes, increasing the mechanical performance without adding too much thickness to the pipe interior, he adds.

(5).jpg)

.jpg)