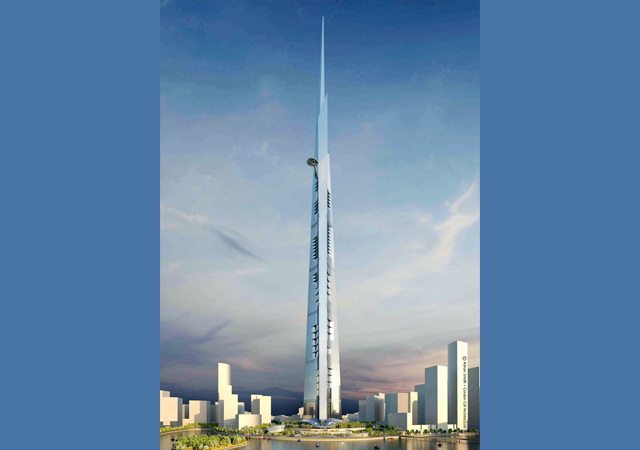

Finlay 694 features high-energy screen boxes designed to process materials across quarrying, mining, sand and gravel, coal, woodchip, and topsoil applications.

Finlay 694 features high-energy screen boxes designed to process materials across quarrying, mining, sand and gravel, coal, woodchip, and topsoil applications.

Finlay has launched two new inclined screeners: Finlay 693 and Finlay 694, as part of the next evolution in its screening portfolio. These revamped models represent a return to the original naming convention, replacing the 693+ and 694+ with streamlined, more cost-effective solutions that deliver high performance and operational efficiency, says the company, which is a Terex brand.

Both models feature high-energy screen boxes designed to process materials across quarrying, mining, sand and gravel, coal, woodchip, and topsoil applications, offering efficient material separation wherever it is needed.

Each screener includes a large hopper with variable speed belt feeder, optional remote tipping or double-deck vibrating grid, and a hydraulics system optimised for power and efficiency. The powerpack is engineered to operate at lower engine speeds for long-term cost savings, and hybrid technology allows operation via onboard engine or external power supply. Simplified folding mechanisms and extra-wide manual catwalks enhance deployment and maintenance, while T-Link telematics with a free seven-year data subscription come standard, says Finlay.

|

The 694 has a triple-deck configuration for high throughput. |

The 693 is equipped with a two-deck screen box featuring a 6.1 m x 1.53 m (20 ft x 5 ft) top deck and a 5.55 m x 1.53 m bottom deck, for high-capacity screening of fine, sticky and dirty materials. Engineered with a powerful, high-energy screen box and optimised material flow design, the 693 excels in mobile screening environments, providing consistent material separation. Its large hopper and variable-speed belt feeder ensure a steady flow of material, while multiple grid options offer flexibility to suit a wide range of site requirements.

Designed with efficiency, reliability and cost-effectiveness in mind, this latest model represents a key step in Finlay’s ongoing commitment to innovation and continuous product improvement.

FINLAY 694

The 694 builds on this with a triple-deck configuration for high throughput, offering two full-size 6.1 m x 1.53 m top and middle decks and a 5.55 m x 1.53 m bottom deck, expanding its screening area to 27 sq m. Additionally, the 694 offers an optional integrated high-volume rinser screen box, significantly increasing its versatility for wet applications. Its large hopper with variable-speed belt feeder ensures consistent, controlled material feed.

The Finlay 694 Inclined Screen is redesigned to deliver exceptional screening performance and operational flexibility, says a spokesman for the company. Purpose-built for high-production environments, the 694 is optimised for clean to moderately contaminated materials.

“By revisiting the original 693 and 694 naming and refining the design, Finlay delivers machines that are easier to transport, more cost-effective to purchase, and aligned with current, real-world operational needs,” says Matt Dickson, Business Line Director for Finlay. “This launch is part of Finlay’s ongoing commitment to product improvement and responsiveness to feedback from our distributors and customers.”

Both models are available to order now.

(5).jpg)

.jpg)