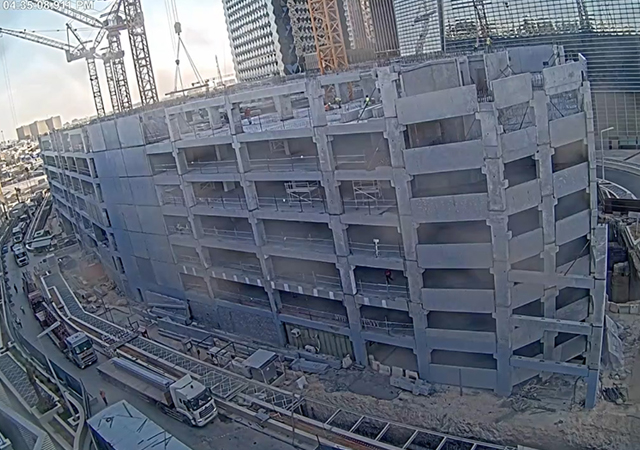

China’s Broad Group has completed the Earth Tower in Abu Dhabi, a 16-storey modular residential project that saw its 259 factory-built modules manufactured in 30 days, then hoisted and installed on site in 96 hours, according to the company.

The project, developed for UAE-based real estate firm Eagle Hills, marks a significant shift toward industrialised construction in the Gulf as the region seeks to meet aggressive sustainability and carbon reduction targets.

The tower serves as a pilot for the Holon building system, a stainless steel modular technology that eliminates the use of concrete. A proprietary bolting method allows rapid assembly and produces virtually no construction waste, significantly lowering the carbon footprint compared with conventional high-rise construction, the company said.

A proprietary bolting method allows rapid assembly on site.

By shifting the bulk of the construction process to a factory environment, Broad Group manufactured the necessary components in 30 days before shipping them for rapid assembly.

Eagle Hills, led by Chairman Mohamed Alabbar, positioned the development as a breakthrough for the UAE’s Vision 2031 goals.

Eagle Hills officials added that the Earth Tower represents a new era for sustainable modular construction in the capital, with plans already under way for future towers ranging from 15 to 30 floors. These subsequent projects are expected to maintain construction timelines of under six months while remaining cost-competitive with conventional building methods and delivering major reductions in emissions, noise, dust, and on-site pollution.

The 150-unit development spanning 168,128 sq ft includes a mix of studio to three-bedroom layouts. Beyond its rapid assembly, the structure is designed to exceed local green building standards through enhanced thermal insulation and upgraded mechanical systems, which Eagle Hills claims will significantly lower long-term energy and water consumption.

A total of 259 factory-built modules were manufactured in 30 days.

“This project shows that speed, quality, and sustainability are not mutually exclusive,” said Shun Li, Deputy General Manager of Broad Holon Company. “By transferring almost all construction processes to the factory, we can effectively ensure quality, significantly shorten the construction period, and reduce construction waste and carbon emissions, while minimising disruption to the surrounding area of the construction site."

Li stated that the industrialised approach ensures higher quality control and a reduced carbon footprint compared to traditional high-rise builds.

The company’s focus on scalability and efficiency was recently recognised at CES 2026. a premier technology trade show, held last month in Las Vegas, US where Broad Group received the Smart Living Award for its contributions to next-generation urban development.

The award honours Broad Group’s Holon modular building system for redefining high-rise construction through ultra-fast deployment, factory-based manufacturing, and significant reductions in carbon emissions, construction waste, and on-site disruption.