The Grand Egyptian Museum (GEM) in Cairo stands as a monumental tribute to Egypt’s illustrious past and its enduring commitment to cultural preservation. Spanning more than 110,000 sq m, the museum is the largest in the world dedicated to a single civilisation, housing treasures that chronicle over 5,000 years of history.

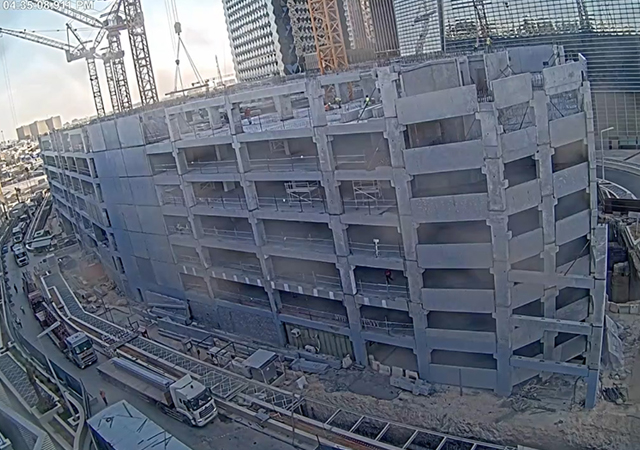

Constructed by the BESIX–Orascom Construction joint venture, the museum has been designed to showcase Egypt’s ancient heritage, including the treasures of Tutankhamun.

To protect these priceless artefacts, the museum required a heating, ventilation and air-conditioning (HVAC) system capable of maintaining unmatched stability in air quality, temperature, and humidity. This demanding challenge called for precise engineering and advanced flow technologies.

In line with these requirements, Armstrong Fluid Technology, a leading manufacturer of intelligent flow equipment, including pumps, valves, heat exchangers and control solutions, in collaboration with Egypt’s Gabtic Engineering, supplied a comprehensive suite of HVAC pumping systems and pressurisation units. The systems were carefully designed to uphold the museum’s stringent climate control requirements while ensuring energy efficiency and long-term sustainability.

The HVAC system has been designed to protect the artefacts the Grand Egyptian Museum houses.

Armstrong’s scope of supply included primary and secondary chilled water pumps, condenser water pumps, hot water primary and secondary pumps, and chilled and hot water pressurisation units. Among the key components delivered were Armstrong’s Design Envelope Sensorless 4300 and VIL 4300 vertical in-line pumps, chosen for their reliability, compact design, and superior energy performance. These intelligent systems, equipped with sensorless control and built-in diagnostics, provide highly efficient and low-maintenance operation, in line with demands placed by a facility of the GEM’s complexity and scale.

Armstrong’s National Sales Manager in Africa Kiran Dharwadkar states: “Our advanced VIL/DE pump technology and Design Envelope solutions were selected for their proven reliability, energy efficiency and seamless integration into complex systems. These intelligent systems deliver exceptional hydraulic performance while minimising footprint and simplifying installation across the museum’s extensive HVAC network. With sensorless control, built-in intelligence and minimal maintenance requirements, Armstrong’s solutions ensure consistent comfort, reduced operating costs and long-term sustainability for this landmark facility.”

“The Grand Egyptian Museum represents not only a cultural milestone for Egypt but also a historic moment in Armstrong’s legacy,” says Qusai Abuabed, Sales Director Türkiye and MEA at Armstrong Fluid Technology. “We are proud to be part of this World Heritage project, contributing our global expertise and advanced technologies to help preserve Egypt’s rich cultural legacy for future generations”.

Hussein El Alfy, CEO of Gabtic Engineering, adds: “Partnering with Armstrong on the Grand Egyptian Museum was a defining moment for Gabtic. The project demanded uncompromising quality, precision and reliability- values that Armstrong consistently delivers. Together, we ensured that every system performed flawlessly to meet the expectations of one of the most significant cultural institutions in the world.”

Armstrong Fluid Technology is an innovator in the design, engineering and manufacturing of intelligent fluid flow equipment, control solutions and optimization technologies.

The company applies advanced approaches such as edge computing, IoT integration, digital twin technology, and demand-based control to optimise mechanical system performance.