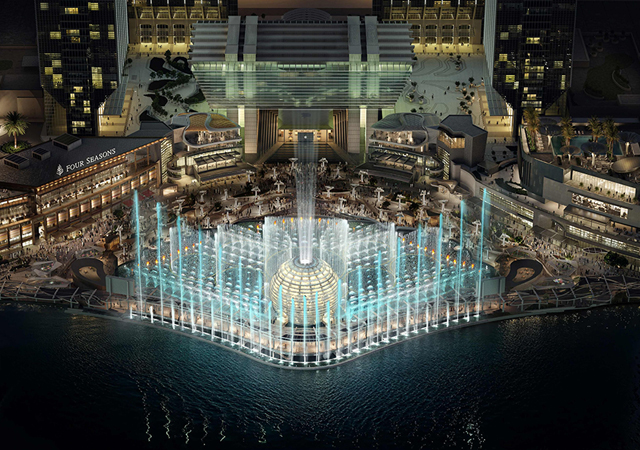

Artist's impression of the front.

Artist's impression of the front.

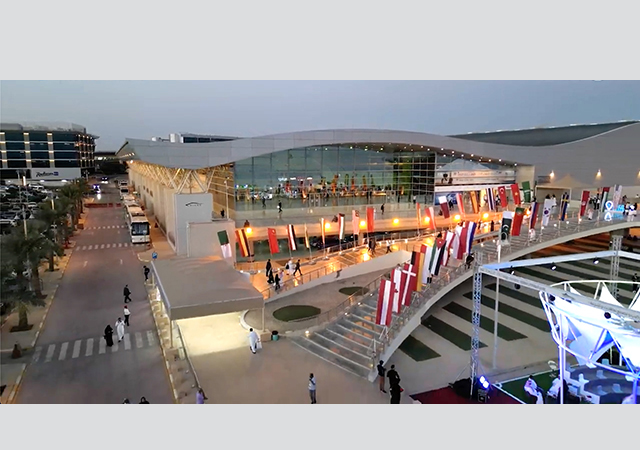

The striking Manar Mall is set to create waves in Ras Al Khaimah, the northernmost emirate in the UAE, when it opens shortly. Due for completion next month (February), the mall boasts the region's biggest indoor amphitheatre in a shopping centre and the first district cooling system to be used in a commercial complex in the Gulf, according to Manar Developments, the client.

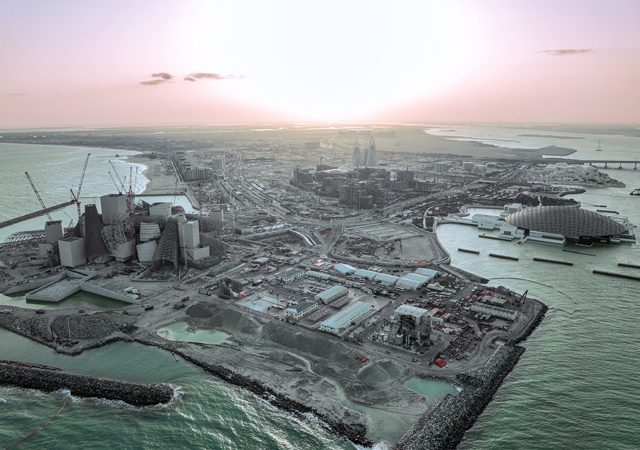

The Dh150 million ($40.85 million) mall is located in the centre of Ras Al Khaimah on the corner of Al Gorm and Bridge Road, on a 160,000 sq m site - most of it reclaimed - sitting directly on the waterfront. About 90 per cent of retail space has already been leased, says Manar Developments.

The project is the brainchild of Sheikh Saud bin Saqr Al Qasimi, chairman of the emirate's Ruler's Court, who first envisaged the development in 1996 with the aim of providing an international-standard shopping and entertainment centre to boost Ras Al Khaimah's economy and tourism potential.

Over a single-level floor plan, the 45,000 sq m complex houses a 12,000 sq m hypermarket, seven-screen cinema, 2,000 sq m family entertainment centre, 110 retail shops, four restaurants, 10 food-court stands, an indoor amphitheatre and exhibition/promotion area, outdoor dining area and watersports facilities. A total of 2,200 open-air landscaped spaces are provided for car parking.

The mall has been designed in accordance with ultra-modern mall concepts that are popular in the US and Europe, by Cadiz Design Group (CDG) of the US, which has placed equal emphasis on the shoppers as well as shop-owners.

''Every effort has been made to ensure maximum exposure for every outlet. In fact, although the original architectural designs included two corridors for shops in the mall, Manar Developments only wanted one corridor to ensure all tenants enjoyed equal exposure,'' Neil Storey, general manager of Manar Developments.

Although the mall is built on a single-level plan, there is scope to increase this to two storeys, if required, for future expansion. The finishing touches are now being put to the complex, work on which started in December 1998.

The mall went through a number of design changes to meet the client's and the tenants requirements as well as to meet the schedule for completion.

Commenting on the design of the mall, Storey says: ''There was a choice of five locations for the mall - the chosen site was deemed best, given its central location in Ras Al Khaimah and its waterfront setting.

''Original designs envisaged the mall as a steel structure, but due to time considerations only the hypermarket was completed as a steel structure. Precast slabs and beams were chosen for the main section of the mall, as they are cost effective and faster to erect. When this decision was made, work on the raft foundations to accommodate a single-level structure was already in progress. It was, therefore, necessary to upgrade the foundations to enable a second level to be added at a future date.''

Other architectural elements include false facades above the shops to give the impression that it is a two-level centre. One wing of the mall has an Arabian design, while the second wing is in a 'Mediterranean' style.

Throughout the construction of the project, Manar Developments enhanced the architectural drawings with embellishments, according to Storey. In the Arabian wing, two towers and a cannon were added to the design, while in the Mediterranean wing, there is a Sphinx structure.

''In the atrium, the original designs had included a tower which would have blocked the view of the stage of the amphitheatre. The tower has been taken out - and this required some structural alterations.

''The designs included the largest indoor amphitheatre in a shopping centre in the Gulf, including changing rooms in the basement and a stage. The stage setting is a first in the UAE.

''Tenants' requirements were also greater than anticipated. For instance, for the seven-screen cinema, the operator Al Massa has strict requirements for soundproofing. Manar Developments had to provide additional blockwork walls/rockwool insulation - and the extra weight required stronger foundations.''

As the mall has been designed for a potential second level, the roof is flat and has a waterproofing membrane which also acts as insulation for the air-conditioning system.

The central atrium has structural glazing, a striking feature of which is that probably no two pieces of glass in the panels are the same size, according to Storey.

There were 1,600 workers on site at the peak of construction. Although concrete with a strength of 40 N/sq mm was specified for the project, a strength of 65 N has been achieved, he adds.

A particular challenge was with the casting in summer - thermometers were placed across the site and casting was stopped when the temperature hit 39 deg C, he points out.

The shops are being handed to the tenants with bare shell furnishing including sprinklers, chilled water pipes and electric meters. Manar Developments encourages the tenants to use different design elements for the shopfronts.

The fire-fighting system comprises sprinklers (wet), hydrants, smoke and heat detectors, fully addressable alarm system, two 500 cu m water tanks (one used for chilled water and the other for potable water, which are interlinked for fire-fighting), electrical and diesel fire pumps (automatic when 4 bar is achieved) and feeder pillars around the building. There is also a central gas system which incorporates an alarm.

A high level of security is ensured at the mall by a close-circuit television (CCTV) which is monitored round-the-clock in a manned control room. The public address system has an override switch which will override the music in the hypermarket/anchor outlets (such as the entertainment centre).

Air-conditioning is provided by a 3,000-tonne centrifugal chilled water system, equipped with fresh air handling units throughout the building and ozonisers to clean the air of dust.

In the car-park, the original design called for 330 light poles which has now been revised to 20 high-mast poles - with 55 lux to 75 lux.

Compactors (wet and dry) are being introduced to handle the garbage from the mall.

Since the original designs had been changed from structural steel to precast, the mechanical and electrical services had to be rerouted.

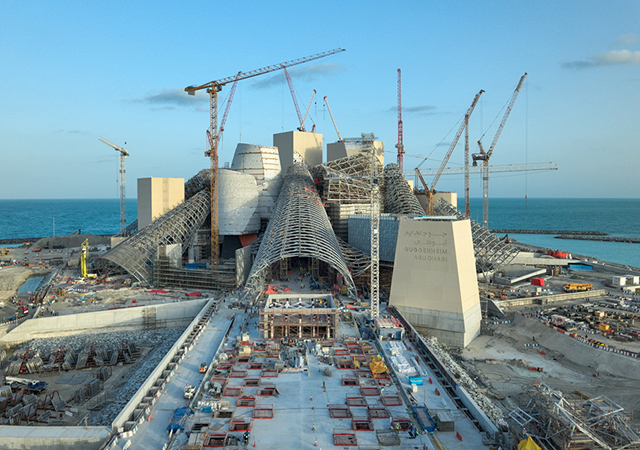

Commenting on project challenges, Storey says: ''In a technical sense, the two spaceframes in the atrium presented a challenge. Their deflection was greater than the glazing contractor would allow - so an extra structure had to be included to allow for this. The spaceframe structure was, at the time, the biggest in the UAE and was lifted, as built, by a 450-tonne crane atop the atrium.

''Another challenge was presented by the groundwater level. The original finished floor level was 3.2 m above groundwater table, but this was raised to 4.27 m above groundwater table. Additional care was taken at the foundation stage because of potential salt water seepage.

''Availability of materials also presented a challenge in the project. In particular, lead time for imports posed something of a problem. For example, shipping of a 3.3 kV panel for the chillers for the hypermarket was delayed. With the opening of the hypermarket having been imminent, two options were open to Manar Developments - either to rent temporary chillers or to airfreight it - in the end, it was airfreighted.

''In the early part of the project, there were problems with the readymix - these were overcome by Al Futtaim Tarmac, who set up an onsite readymix laboratory which ensured very strong foundations with 99.6 to 99.8 per cent compaction ratios.''

A unique feature of the development was that Manar Developments installed the first district cooling system for commercial use in the Gulf, under a joint venture with Tabreed of Abu Dhabi. The system is a 10,000-tonne water capacity plant. Manar Mall needs 3,000 tonnes, with the remaining 7,000 tonnes to be piped to other customers in Ras Al Khaimah.

With regards to the sewage treatment plant (supplied by Metito), the original plans were for a cast in-situ system. Now there are three 100 cu m per day capacity tanks, from which the treated effluent is used for the landscaping.

Finally, the original MEP specifications did not comply with UAE standards - therefore, Manar Developments engaged consultant WS Atkins and Partners Overseas to redo them.

Unity Contracting Company (Unco) was responsible for the civil works on the project. The subcontractors include Tiger Steel (steel structure); Rasana Contracting Company (spaceframe); United Precast Concrete (precast concrete elements); Built Middle East (fire-fighting, plumbing and gas); ETA (air-conditioning, electrical contractor for fan coil units and piping); Mitsubishi (generators); Extra Co (false shopfronts); Arctic (ceilings, flooring and partitions); NGIT (waterproofing); Alico (glazing and aluminium); RAK Ceramics; Metito (sewage treatment plant; Orient Irrigation (landscaping and irrigation); and Emirates Road Contracting - ERC (asphalting).

.jpg)

.jpg)

Doka (2).jpg)

.jpg)

.jpg)

.jpg)