HRH Prince Abdulaziz bin Salman celebrating the completion of the first H-Class gas turbine in the kingdom, together with the Gesat team.

HRH Prince Abdulaziz bin Salman celebrating the completion of the first H-Class gas turbine in the kingdom, together with the Gesat team.

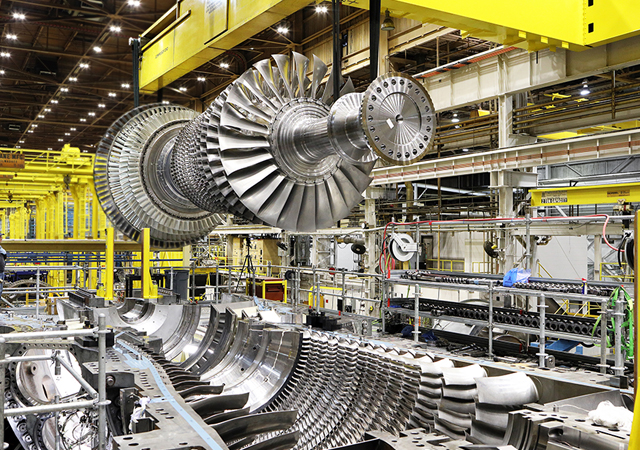

In a significant stride for the ‘Made in Saudi’ initiative and a high technology triumph for the Kingdom, GE Vernova has celebrated the rollout of its first H-class gas turbine unit from the GE Saudi Advanced Turbines (Gesat) facility in Dammam.

This milestone, achieved through extensive local collaboration and investment, marks a high point in Saudi Arabia’s journey towards energy transition and industrial self-reliance.

In an exclusive interview with Gulf Construction’s Sree Bhat, Hisham Al Bahkali, President of GE Vernova in Saudi Arabia, emphasises that the H-Class turbine is GE Vernova’s most powerful and efficient model, designed to convert natural gas to electricity in the most cost-effective manner.

|

|

Al Bahkali ... a great step towards building local capabilities and skillsets. |

“The high efficiency and hydrogen readiness of our H-class turbines support the country’s energy transition,” Al Bahkali notes. “These turbines can ramp up or down rapidly, ensuring grid stability as more renewables are integrated into the energy system.”

“Being able to roll out this highly advanced technology from a Saudi factory is a great step towards building local capabilities and skillsets, and is a result of continuous knowledge transfer and investment in the local Saudi workforce.

“The rollout of the first HA unit completed at Gesat is testament to our efforts in further deepening power sector capabilities in the kingdom, and we are already working on the next milestones on this journey,” he says.

Gesat’s accomplishments are impressive. The facility has exported more than 200 modules to about 40 countries across four continents, contributing to the generation of more than 11 gigawatts (GW) of electricity – enough to power over 8.2 million homes. This success story is driven by extensive training for Saudi nationals, including more than 4,100 hours of instruction in engineering, quality assurance, and technical functions through GE Vernova’s facilities in the US and France, he says.

|

|

Rotor assembly of GE Vernova’s H-Class gas turbine (photo taken in Greenville, US). |

To meet the rising demand for higher capacity and efficiency, GE Vernova is making further investments in the Gesat facility. These upgrades are in preparation for manufacturing the latest H-Class model, the 7HA.03 gas turbine. “These investments will further elevate the knowledge and skills of our Saudi talents as they work on GE Vernova’s most advanced gas turbine technology,” Al Bahkali remarks.

Excerpts from the interview with Hisham Al Bahkali

Congratulations on the rollout of the first H-Class gas turbine completed at the Gesat facility. How important is this milestone for your company and the overall energy sector of Saudi Arabia?

Thank you, we are very proud to celebrate this achievement, which is a significant milestone for both GE Vernova and the capabilities of the kingdom’s energy industry. The H-Class is GE Vernova’s most powerful and most efficient gas turbine, and offers one of the most cost-effective conversions of natural gas to electricity in their class. The high efficiency and hydrogen readiness of our H-class turbines can support the country’s energy transition, as the turbines can rapidly ramp up or down quickly to support grid stability as more intermittent renewables are integrated into the energy system.

Being able to roll out this highly advanced technology from a Saudi factory is a great step towards building local capabilities and skillsets, and is a result of continuous knowledge transfer and investment in the local Saudi workforce.

The significance of this achievement for the kingdom’s energy sector was underscored in the speech of His Royal Highness Prince Abdulaziz bin Salman, Minister of Energy, who came to celebrate together with the entire team at the Gesat facility; the team was immensely honoured and proud by his presence and recognition.

Can you provide an overview of GE Vernova’s mission and vision for Saudi Arabia?

GE Vernova has close to 90 years of legacy in the kingdom, and today GE Vernova’s power generation solutions are generating around 50 per cent of the country’s power. This long-term engagement, as well as recent investments we have made, are reflecting our strong commitment to advancing the country’s goals for energy security, efficiency, economic diversification, and talent development under Saudi Vision 2030. The rollout of the first HA unit completed at Gesat is testament to our efforts in further deepening power sector capabilities in the kingdom, and we are already working on the next milestones on this journey.

What motivated the establishment of the GE Saudi Advanced Turbines (Gesat) facility in Saudi Arabia? And how does Gesat contribute to Saudi Arabia’s economic diversification, particularly in the context of Vision 2030, localisation and technology transfer?

Gesat has been set up to enhance local capabilities in Saudi Arabia, with the aim to empower Saudi workforce to assemble and manufacture heavy-duty gas turbines for both domestic needs and for export worldwide, supporting the kingdom’s strategy under Saudi Vision 2030 to diversify its economy and grow non-oil exports.

Gesat has already come a long way on this mission, having exported more than 200 modules from Saudi Arabia to about 40 countries across four continents, contributing to the generation of more than 11 gigawatts (GW) of electricity – enough to power more than 8.2 million homes.

Last year, the Gesat team had reached another significant milestone by completing three 7F.05 gas turbines for the cogeneration plant and desalination plant at the Tanajib project.

To give you an example, the technology transfer to the Saudi nationals at Gesat included more than 4,100 hours of training in engineering, quality assurance and technician functions through GE Vernova’s facilities in the US and France.

How has the joint investment with Dussur contributed to the development and success of the Gesat facility?

The collaboration with Dussur has been very fruitful in setting up this unique and first-of-its-kind facility in Saudi Arabia, and making it run successfully. GE Vernova and Dussur have been sharing the same vision of a factory where highly skilled and well-trained Saudi engineers and technicians work on components, modules, and entire heavy-duty gas turbines ‘Made in Saudi’ for the power needs of the kingdom and for export, contributing to the growth of non-oil economy under Saudi Vision 2030.

What are the long-term goals for the Gesat facility in terms of production capacity and technological advancements? And how do you see the opportunities?

Saudi Arabia plans to transition its energy mix to 50 per cent renewable energy and 50 per cent natural gas by 2030, fading out the use of liquid fuels. This will require significant investments in existing and new gas power infrastructure, and Gesat is purpose-built to support this strategy with world-class technology.

We are making further investments in the Gesat facility infrastructure and tooling to cater for GE Vernova’s latest H-Class model, the 7HA.03 gas turbine, in response to the demand for higher capacity and efficiency engines in the kingdom. These investments will further increase the knowledge and skillsets of our Saudi talents as they will be working on GE Vernova’s most advanced gas turbine technology.

Our company has recently been awarded an order for six 7HA.03 gas turbines and two 7E.03 gas turbines for the Taiba 1 and Qassim 1 power plants in Saudi Arabia. Four of the 7HA.03 units are expected to be rolled out of Gesat, which demonstrates the trust that our customers have in the capabilities of our team in Saudi.

Can you elaborate on the key features and innovations of the H-Class turbine?

The HA is GE Vernova’s most advanced gas turbine, with efficiency rates up to 64 per cent and power output up to more than 800 MW in combined cycle operation. The HA has a combustion system that enables expanded fuel flexibility to operate on various gaseous fuels that can also be blended.

Ready to further reduce carbon emissions, the H-Class is capable today of blending up to 50 per cent hydrogen (H2) into the natural gas for a joint combustion process, with a future technology pathway to 100 per cent! At that point, power producers will be able to run an 800+MW gas turbine with zero carbon emissions in the combustion process. This H2-capability shifts gas power from a transition to a destination technology, and will make it an important cornerstone of a net-zero ecosystem, which Saudi Arabia aims to reach by 2060. Existing units can be upgraded with H2-capability, so that GE Vernova customers can keep their assets running on the long term and maximise the return on their investment.

In addition to providing dependable baseload capacity, the HA also comes with high flexibility to balance varying loads on the grid, providing a turndown capability to more than 30 per cent load, and an optional park mode at 7-15 per cent load. These features make GE Vernova’s H-Class such a valuable technology for an energy strategy like Saudi Arabia’s that aims at adding high ratios of renewable sources to the mix.

What were the major challenges associated with the production of the turbine in Saudi Arabia and how were they overcome?

The most important task was the knowledge transfer to the Saudi team. We wanted to ensure they have all the skills, tools, and safety procedures in place to work on this high-tech equipment successfully, and I am happy to say that the transfer was a great success. After attracting local talents, we enabled them to develop their capabilities through intensive exchange with global manufacturing facilities and through world-class training programmes, including hands-on experience under expert guidance and supervision. The local team was eager to learn and apply the knowledge, working together closely with each other and with the global GE Vernova team.

Setting up a facility to roll out advanced technology like GE Vernova’s H-Class requires all stakeholders to work together towards the same goal. For Gesat, this has clearly become a success story; our suppliers, customers, end-users and government bodies all played a positive role in Gesat’s goal of strengthening ‘Made in Saudi’ capabilities, and we are very happy to see our dream come true to roll out one of the world’s most advanced gas turbines from a facility in the kingdom.

GE Vernova has signed an MoU with the Saudi Export-Import Bank to enable exports from Saudi Arabia. What are the key products you seek to export and which are your target markets? And how big is the market?

The Memorandum of Understanding (MoU) with the Saudi Export-Import Bank (EXIM) aims at enabling the export of advanced power generation technology to countries worldwide. Until today, components and modules from Gesat have been exported to over 40 countries, and we are expecting the number of target countries to grow further. The more than 200 modules that have already been exported include fuel control, air extraction and GT drains modules, as well as upper enclosure modules. We will continue to work on modules and components that can be exported, and, in addition, the team now has the capabilities to export entire heavy-duty gas turbines from Saudi Arabia, like F-Class and H-Class.

The demand for highly efficient and hydrogen-ready gas turbine technology worldwide is high; in its Q2 gas market report, the International Energy Agency (IAE) forecasts global gas demand to grow by 2.3 per cent in 2024, primarily driven by fast-growing Asian markets, North America and the Middle East. IAE also expects 50-60 GW of new gas-fired power capacity to come online per year. The Gesat facility in Dammam is ready to respond to this growing global demand.

What are GE Vernova’s plans for expansion and innovation in Saudi Arabia and the region?

Gesat is part of the Gemtec campus (GE Manufacturing and Technology Center), which is also home to our largest gas turbine service shop in the region. On the same campus, we have opened our regional Decarbonization Center of Excellence where we will perform research and development to drive further innovation in technology that can help to reduce or avoid carbon emissions.

Gesat itself will further grow capabilities by enabling the team to roll out GE Vernova’s latest H-Class technology, the 7HA.03, which is even larger and more efficient than the 7HA.01 that they have rolled out recently.

Moreover, our Grid Solutions business operates the Khobar Integration Facility (KIF) which is another Center of Excellence in Research & Development, manufacturing, service and repairs for grid technology.

We are also making efforts to further localise by continuously looking to qualify local suppliers and further increase the Saudi content in our technology Made in Saudi.

What are some of the major projects that GE Vernova is currently working on in the kingdom?

One of the most significant projects are the Taiba 1 and Qassim 1 power plants I had mentioned earlier – GE Vernova will deliver six 7HA.03 units, four of which will be Made in Saudi at Gesat, as well as two 7E.03 gas turbines. Taiba 1 and Qassim 1 are expected to be among the most efficient power plants in the kingdom and will deliver up to 3.8 gigawatts of electricity to the grid in total.

Another interesting one is the fuel conversion project at Saudi Electricity Company’s (SEC) 5 million sq m Power Plant 10 (PP10) in Riyadh that will switch the turbines from running on liquid fuels to natural gas (that is, lower carbon emissions). Riyadh’s PP10 is one of the largest combined cycle plants in the world. Powered by 40 of GE Vernova’s 7E gas turbines, PP10 produces about 3.5 gigawatts of energy, powering up to 875,000 homes in Saudi Arabia.

How does GE Vernova incorporate sustainability and environmental responsibility into its business practices?

GE Vernova has been purpose-built to drive the energy transition with the aim to reduce carbon emissions. Addressing the climate crisis is an urgent global priority and we take our responsibility seriously, as we continue to electrify the world while simultaneously working to help decarbonise it.

We have just launched our new sustainability framework, and its four pillars integrate all of our businesses and technology toward helping to build a more sustainable electric power system. We are committed to achieving carbon neutrality in our operations (Scopes 1 and 2) by 2030. To achieve this goal, our businesses are making operational investments in energy efficiency, reducing emissions from the grid through smart power sourcing, and using lean practices to eliminate energy waste. We’re also committed to a net zero ambition for 2050 for the Scope 3 emissions from our sold products.

We also seek alignment of our operations with the United Nations (UN) Sustainable Development Goals (SDGs), which set out 17 objectives to help nations address our most pressing global challenges, from climate change to inequality. Currently, we see close alignment between 10 of the 17 SDGs and our business strategy and sustainability priorities. To give you some examples, these 10 SDGs include Affordable and Clean Energy, Responsible Consumption and Production, Partnerships for the Goal, and Gender Equality.

.jpg)

(1).jpg)