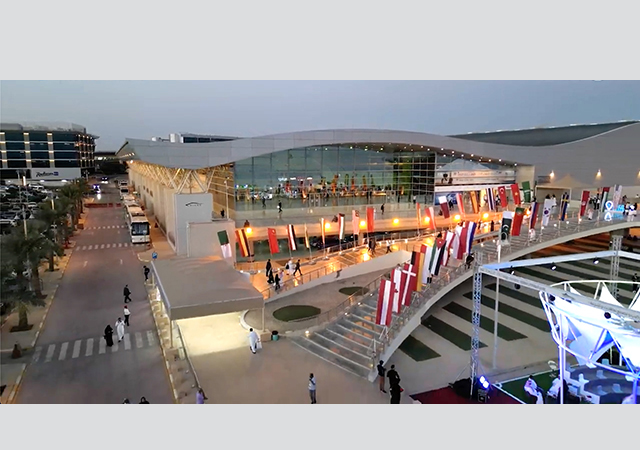

Al Nafie Metal Industries fabricated large-scale structures for the Makkah arches.

Al Nafie Metal Industries fabricated large-scale structures for the Makkah arches.

Al Nafie Group, a leading Saudi steel trading and fabrication and erection major, says it has witnessed a year of significant strategic growth, aligning with Saudi Arabia’s industrial transformation initiatives under Vision 2030.

The group comprises Al Nafie Steel, which has been trading in iron and steel of various specifications from different sources since 1979, and Al Nafie Metal Industries, which offers comprehensive steel fabrication and erection services for major engineering, procurement and construction (EPC) projects, ranging from power and petrochemical plants to food processing factories.

Speaking to Gulf Construction magazine in an exclusive interview, General Manager Majed Al Nafie, says Al Nafie Metal Industries has expanded its presence and technical capabilities within the kingdom’s steel fabrication and erection sector. This growth is supported by an expanding project portfolio, investments in advanced machinery, and strategic partnerships.

“Our operations have grown in both scale and sophistication with the integration of cutting-edge fabrication technologies. This includes the addition of high-precision laser cutting machines, beam line and plasma cutting systems, as well as EGW (electro-gas welding) and AGW (automatic girth welding) machines. These upgrades enable us to fabricate complex structures and large-diameter tanks with unmatched quality and efficiency, supporting large-scale industrial, energy, and infrastructure projects,” he emphasises.

|

|

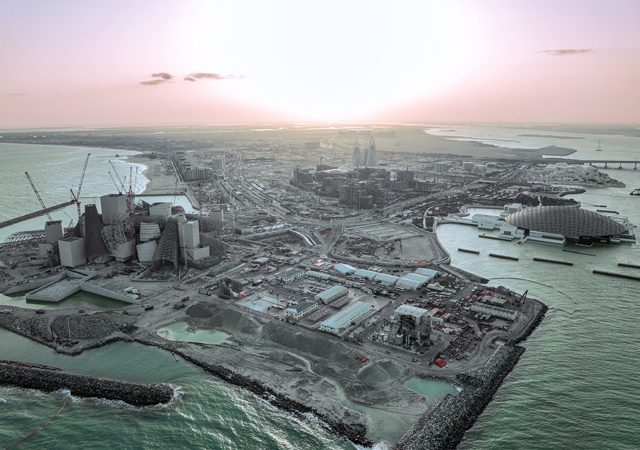

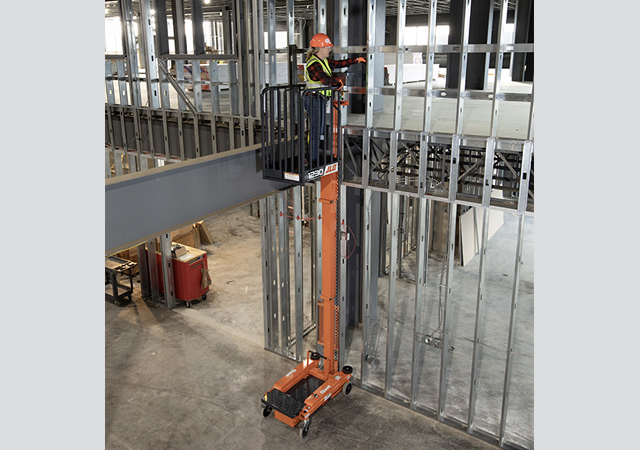

Al Nafie Metal Industries offers comprehensive steel fabrication and erection services for major engineering, procurement and construction (EPC) projects. |

Al Nafie Metal Industries is positioning itself as a one-stop shop for steel fabrication needs across various industries. Its portfolio includes steel structures, storage tanks, pressure vessels, process and power piping and pipe spools, stacks, ducts, diverters, heat recovery steam generators (HRSG) casings, silos and hoppers, catering to sectors like oil and gas, petrochemicals, power generation, and desalination.

Al Nafie Metal Industries benchmarks its processes against the best-in-class companies and practices. It relies on machine automation for mass production and utilises the latest software for design, nesting, cutting, welding and painting and delivery.

|

|

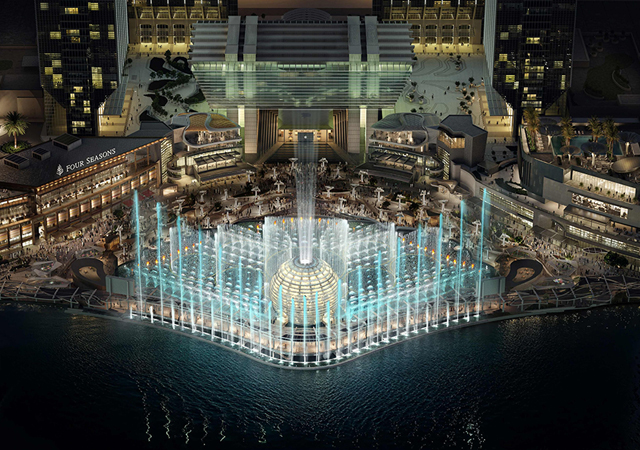

Al Nafie Metal Industries carried out the fabrication and erection of demineralised water tanks, fire and service water tanks for the Rabigh Power Plant. |

Al Nafie cites some of the several landmark projects that demonstrate the depth of its capabilities. These include:

• Doosan/ACWA Power Shuaibah III IWP Desalination Plant: Al Nafie Metal Industries has played a pivotal role in the fabrication and erection of critical steel structures for this strategic facility, contributing to Saudi Arabia’s water security and sustainable utility goals.

• Elswedy PSP/ Saudi Electricity Company (SEC) Rabigh Power Plant: The company has successfully completed the fabrication and erection of demineralised water tanks, fire and service water tanks, meeting stringent Elswedy PSP/SEC and international engineering standards.

• Water Transmission Company’s Al Lith Water Tanks project: Al Nafie Metal Industries will prefabricate and erect two large-diameter steel storage tanks with a diameter of 54.00 m and a height of 11.65 m (Tank No. NMI-TANK-25770-001 A/B). These tanks are designed for long-term service in critical water infrastructure networks.

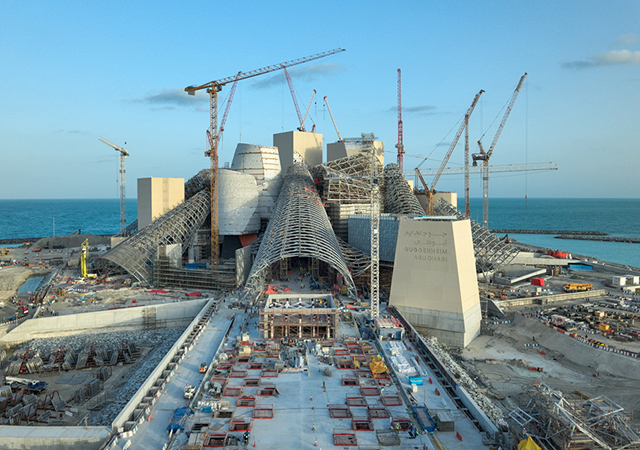

• ASME U Stamp pressure vessels: The company produces ASME U Stamp-certified high-pressure vessels for petrochemical and industrial clients, a capability that diversifies its technical services and addresses a critical need in these sectors.

• Siemens/RUH-KAIA Airport T1 and T2: Al Nafie Metal Industries provided fabrication and erection services for the steel structures that support key systems at the terminals of Riyadh’s King Khalid International Airport and Jeddah’s King Abdulaziz International Airport, contributing to the national aviation infrastructure.

Al Nafie Metal Industries also maintains ongoing fabrication programmes with clients including Saudi Aramco, National Water Company (NWC), Saline Water Conversion Corporation (SWCC), Alfanar, Rawabi and SEC.

|

|

An ASME U Stamp-certified high-pressure vessel produced by Al Nafie Metal Industries. |

“Collaborations with major international engineering firms such as Doosan, Elswedy, Mapa Group, L&T, and national contractors like Saudi Binladin Group (SBG), Nesma and Partners and UCC and consultants like DAR further underscore our reputation as a dependable and advanced industrial partner,” Al Nafie states.

Looking forward, Al Nafie Metal Industries will actively engage in the design, fabrication, and erection of steel structures for several upcoming Saudi football stadiums, aligned with the kingdom’s Vision 2030 ambitions and the 2034 FIFA World Cup preparations, he reveals.

“With a dedicated team, world-class facilities, and a forward-looking approach, we are proud to contribute to the kingdom’s transformative journey across the water, energy, transportation, and cultural infrastructure sectors,” Al Nafie adds.

Al Nafie Steel

Meanwhile, Al Nafie Steel continues to lead the steel distribution sector with a sharp focus on innovation, regional expansion, and support for national megaprojects.

|

|

Al Nafie has carried out fabrication of steel components for overhead cranes. |

In a bid to enhance its ability to serve clients more effectively across Saudi Arabia and strengthen its logistics and delivery network, the company has launched an expansive drive. In line with this strategy, Al Nafie Steel is set to launch three new branches strategically located in the Northern, Southern, and Eastern regions of Saudi Arabia.

“In terms of product development, we have recently introduced a brand-new wear-resistant plate designed for high-demand industrial applications, along with new grades of tool steel and aluminium that meet the evolving needs of the construction, manufacturing, and energy sectors. These additions further diversify our portfolio and reinforce our position as a trusted materials partner across the region,” he states.

Al Nafie concludes by emphasising the group’s contribution to local content and value chain development, particularly through its involvement in providing specialised steel products for the infrastructure for the Saudi Football Stadium projects.

.jpg)

.jpg)

Doka (2).jpg)

.jpg)

.jpg)

.jpg)