Awan .. committed to quality.

Awan .. committed to quality.

Maromix, a Saudi pioneer in the solid surfacing sector, is set to open a new showroom in Riyadh early next month. The Dammam-based company has recently installed new machinery which has effectively doubled its production capacity for kitchen cabinets and vanity sets, according to Maqsood Awan, general manager.

The company's wood products and kitchen division manufactures kitchen cabinets and vanity cabinets made of solid oak, mahogany and teak wood. These product ranges are suited for hotels, restaurants, hospitals, clinics, banks, shops, airports and housing compounds, says Awan.

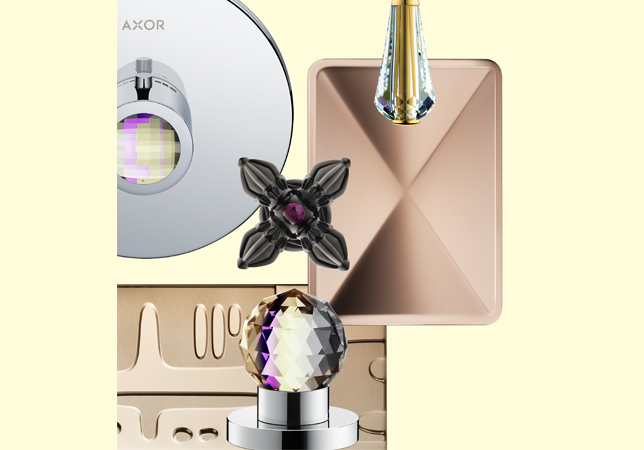

Maromix claims to have achieved a 'first' in the Middle East when it cast the first polymer-bonded mineral-based solid surface at its plant in Al Khobar. Today, the firm has broadened its scope of operations to complement its core activity and enhanced its product range to include a number of new finishes.

In June, Maromix launched its latest innovation, the onyx finish, which resembles marble and is designed for cladding decorative columns, vanity tops, reception counters, among other applications. Other finishes recently introduced by the firm include Stonemix and Marblemix, which resemble natural stone and marble, respectively.

Maromix has been involved in a large number of projects in Saudi Arabia. It has undertaken several jobs for Saudi Aramco involving supply of counter and vanity tops and sinks and Saudi Iron and Steel Company (Hadeed) for its Ghazlan villas complex. It has also catered to the requirements for kitchen units and vanities of many housing compounds for clients such as Sharq, Petrokemya Jubail, and National Commercial Bank. It recently supplied kitchen units to the Holiday Inn in Hasa and the Meridien Hotel in Al Khobar.

Elaborating on the Maromix solid surfacing material, Awan says: "Maromix products exhibit characteristics which set them apart from other surfacing products.

''The ability to join Maromix products in an inconspicuous manner allows for built-up edges in a variety of thicknesses while enabling joining of sheets and bowls in virtually unlimited combinations. The end product is smooth and cleanable and has indiscernible seams.

''The homogeneous nature of Maromix allows the material to be cut and shaped while maintaining the same surface appearance. Maromix products are also offered in veined patterns.

''While featuring a textured look, Maromix surfaces are actually smooth, impermeable and are resistant to thermal shock, impact, stain and discolouring and hence, durable.

''The non-porous nature of Maromix solid surface products allows it to be installed in wet areas such as tub and shower walls, tub surrounds, fountains, functional planters, vanity and kitchen bowls. Due to the unique process for seaming Maromix products, these bowls can be adhered to sheet products with virtually seamless results.

''The solid surface sheets can be applied in a variety of vertical applications such as tub and shower walls, wainscotting and other decorative or functional vertical applications.

''Maromix solid surfaces may be easily cleaned using conventional cleaning agents such as ammonia-based liquid cleaner, soap and water or hard surface cleaners which will get rid of grease and most stains. Should accidental damage ever occur, it can be easily repaired with just light sanding.

Maromix is committed to providing customer satisfaction, quality and after-sales services, he points out. Its customer services staff include experienced and dedicated engineers as well as technical experts with the know-how to provide enhanced support and solve problems.

''Maromix products are covered by 10 years warranty - assuring the client of long-term performance and defect-free material, provided the product is fabricated, installed and used in accordance with the guidelines and requirements,'' Awan concludes.

.jpg)

.jpg)

.jpg)