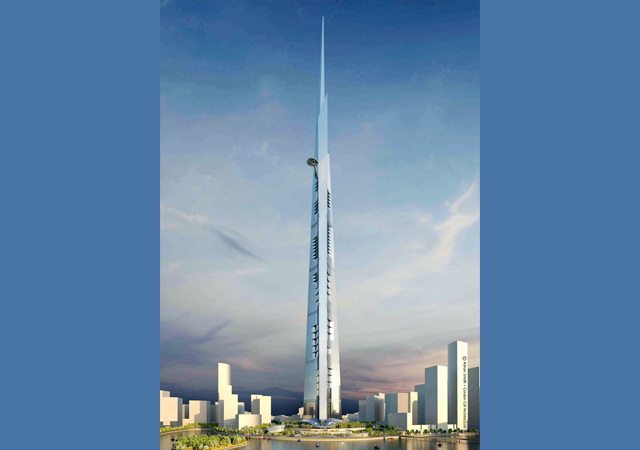

Capitol Dome in San Juan, Puerto Rico

Capitol Dome in San Juan, Puerto Rico

The 11th annual ACI Excellence in Concrete Construction Awards celebrated outstanding and innovative concrete projects from around the world. The Overall Excellence honour was awarded to the Capitol Dome in San Juan, Puerto Rico, which also won first place in the Repair and Restoration Structures category during the ACI Concrete Convention on October 27.

The awards were established to celebrate the most visionary projects in the concrete industry and to offer a platform to acknowledge global advancements in concrete innovation, technology, and excellence. To be eligible for the ACI Excellence in Concrete Construction Awards, projects must be nominated by an ACI Chapter, International Partner, or submitted through self-nomination.

In addition to the highest honour, the Overall Excellence award, additional projects recognised during the ACI Excellence in Concrete Construction Awards include:

• Repair & Restoration

o 1st Place: Capitol Dome, in San Juan, PR, US - The Capitol Dome in San Juan, Puerto Rico, was restored over two years to fix structural damage while keeping its historic character. Modern techniques like carbon-fiber reinforcement and micro-cement injections were used to ensure it will last for generations.

o 2nd Place: UCSD York Hall, in La Jolla, CA, US - The UCSD York Hall seismic improvements project in La Jolla, California, involved retrofitting and strengthening this 1966 historic building while preserving its architectural heritage.

• Decorative Concrete

o 1st Place: California Firefighters Memorial, in Sacramento, CA, US - The California Firefighters Memorial in Sacramento honours more than 1,500 firefighters who have died in the line of duty since 1850. Combining monuments, statues, and carefully crafted decorative concrete, the memorial creates a meaningful and lasting space for reflection.

o 2nd Place: Campus Development Project of Indian Institute of Technology Hyderabad (Phase-2) – Package 3B, in Telangana, India - The Indian Institute of Technology Hyderabad Phase-2 campus integrates advanced architectural form-finish concrete across lecture halls, department buildings, dining halls, and core labs.

• Low-Rise Structures

o 1st Place: The Altamura Home, in Santa Rosa, CA, US - Designed and built for maximum efficiency, the Altamura residence in Santa Rosa, California, is a Net Zero home that uses a Passive Geo Insulated Concrete Shell to naturally regulate temperature without mechanical systems.

o 2nd Place: Project Heat, in Chicago, IL, US - This two-storey, 250,000-sq-ft warehouse is Chicago’s first multi-level facility allowing full-sized semi-truck access on both floors. With clear spans up to 60 feet, a rooftop parking deck, and over 73,000 cubic yards of concrete, the project used precision pouring and sustainable methods to create a strong, efficient, and durable structure.

• Mid-Rise Structures

o 1st Place: City of Hope – Hope Plaza, in Duarte, CA, US - Hope Plaza is an eight-storey outpatient facility in Duarte, California, with 352,000 sq ft of space. Its design features colourful walkways, custom seating, and a cascading fountain, blending structural and landscape concrete to create a welcoming, durable space for patients and visitors.

o 2nd Place: National Taiwan University Humanities Hall, in Taipei City, Taiwan - The Humanities Hall is a modern academic building at the National Taiwan University in Taipei (TIE-PAY) City, Taiwan, linking campus, heritage, and city, with a 50-meter sky bridge. Designed with a vision for longevity of over 100 years, the Hall aspires to stand as an emblem alongside their iconic Main Gate and College of Liberal Arts.

o Honourable Mention: Shanghai Grand Opera House, in Shanghai, China - The Shanghai Grand Opera House is known for its striking spiral staircase shaped like an open Chinese fan. Built with prefabricated and cast-in-place ultra-high-performance concrete, it achieves long cantilevers while cutting carbon emissions, making it both a structural and cultural landmark.

• High-Rise Structures

o 1st Place: Satsukita 8-1, in Sapporo, Hokkaido, Japan - Satsukita 8-1 is the tallest skyscraper in Hokkaido, Japan, at 48 storeys, rising 175 m. Designed for cold, snowy conditions, the building uses reinforced concrete for earthquake and wind resilience, with high-strength columns, girders, and shear reinforcement.

o 2nd Place: The Ayer, in Seattle, WA, US - The Ayer is a 45-storey, 576,000-sq-ft residential tower in Seattle, Washington. Its cast-in-place concrete structure features 8-inch post-tensioned slabs, perimeter cantilevers up to 12 feet, and a shear wall core for seismic and wind resistance.

• Infrastructure

o 1st Place: Romaine-4 Generating Station, in Havre-St-Pierre, QC, Canada - Romaine-4 is the final hydropower plant of the Romaine complex in Quebec, Canada, now producing 1,550 megawatts of clean electricity. Built in a remote region of Quebec, the project relied on close collaboration with local and indigenous communities.

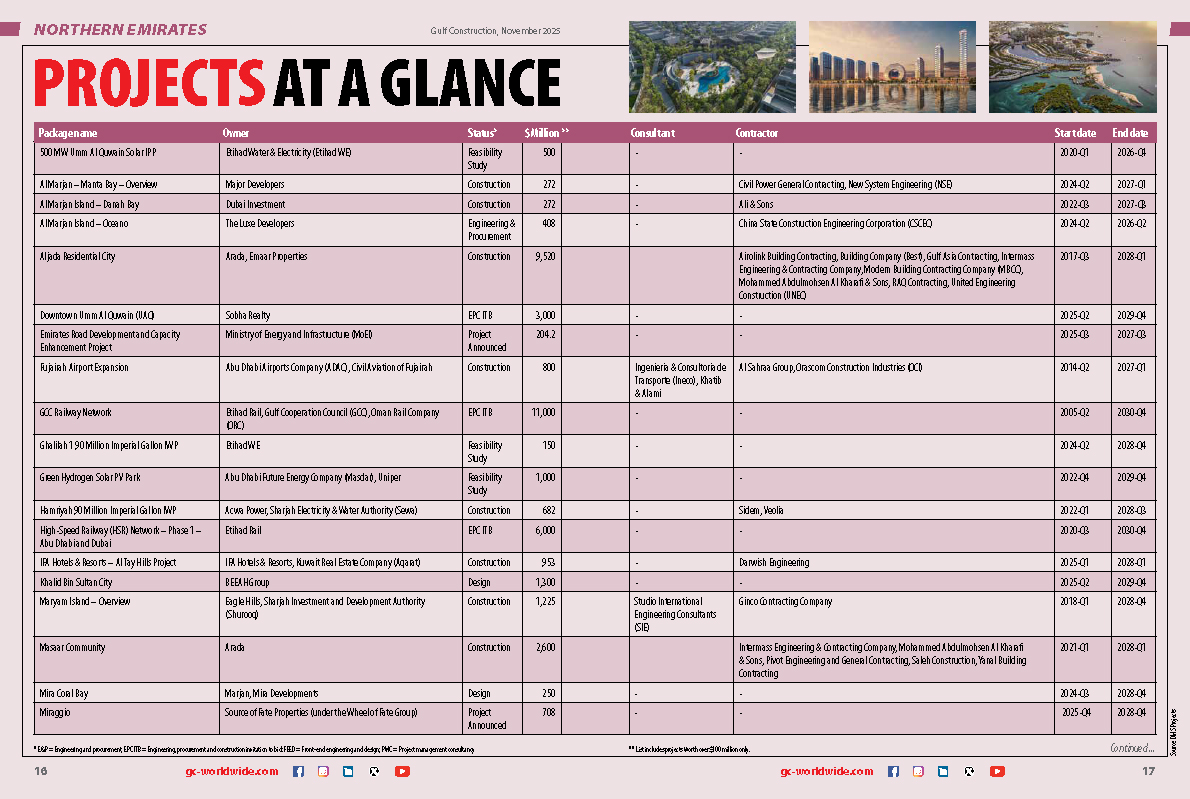

o 2nd Place: King Salman Energy Park (SPARK), in Abqaiq, Eastern Province, Saudi Arabia. SPARK, a cornerstone of Saudi Arabia’s Vision 2030, delivers world-class industrial and energy infrastructure across 14 sq km of Phase 1.

• Bridges

o 1st Place: Delhi-Meerut Rapid Rail Transit System, in Meerut, India - India’s first semi-high-speed rail in Meerut connects regional nodes with a dedicated corridor, cutting travel time between Delhi and Meerut to 55 minutes. The 42-km viaduct uses precast segmental box girders and portal beams to minimise construction disruption.

o 2nd Place: Cebu Cordova Link Expressway, in Cebu City, Philippines - This 8.9-km expressway on Mactan Island connects Cordova to Cebu City, helping to ease traffic and support the local economy. Built despite COVID and Super Typhoon Rai, it used 185,000 cubic meters of concrete and advanced construction technologies like a launching gantry and large-diameter paver.

• Flatwork

o 1st Place: Low Carbon Concrete: Bus Charging Station, in Salt Lake City, UT, USA – Low Carbon Electric Bus Charging Station demonstrates innovative low-carbon concrete using Roman Cement’s patented technology, improving cement hydration, particle packing, and workability while reducing cement use, cost, and CO2 emissions by 20%.

o 2nd Place: Apron and Taxiway Project for T3, TTIA, in Taoyuan City, Taiwan - The project installed over 13,000 concrete slabs at Taoyuan Airport, designed to handle heavy aircraft, extreme weather, and long-term durability. Advanced techniques like LIDAR leveling and specialized curing ensured flat, strong, and carbon-conscious pavement under active airport operations. -TradeArabia News Service

(5).jpg)

.jpg)