Purpose built ... Zamil project executed successfully.

Purpose built ... Zamil project executed successfully.

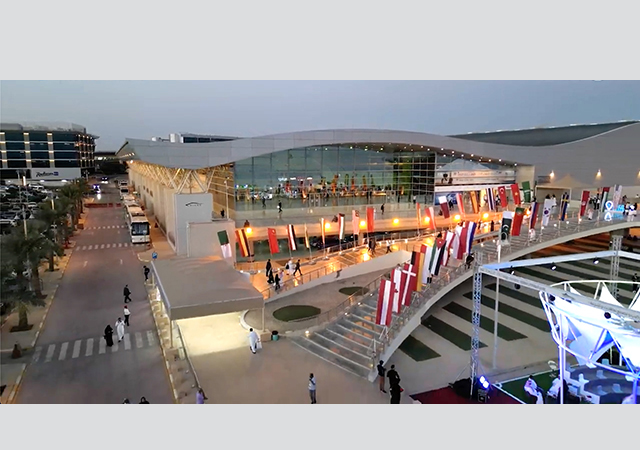

ZAMIL Steel, which holds a global leadership position in the design, manufacture and supply of pre-engineered steel buildings (PEBs), has provided two purpose-built steel structures covering a total area of 62,318 sq m to house the production facilities of Future Ceramics.

Zamil Steel started work on the project in December 2006 and completed its contract in September last year. Its scope of work included the design, fabrication and supply of two steel buildings – Building One, with nine areas; and Building Two, with eight areas.

Commenting on the execution of the project, Hatem Turki, marketing manager of Zamil Steel PEB Unit, says: “We didn’t face major challenges as the project was very well studied, planned and managed, especially since we were involved from the early design stages.”

Zamil Steel has, over the past 32 years, grown from a local single-division company into a leader in the growing field of steel fabrication in Asia, Africa and Europe. Its sphere of activity has also expanded to include design, manufacture and supply of conventional steel structures and process equipment, transmission and telecommunication towers, and open web steel joists and decking.

The Saudi-based company, which has supplied more than 50,000 buildings worldwide, has hundreds of orders in hand for supplying PEBs to various industrial and commercial sectors, such as production facilities, hypermarkets, showrooms, warehouses, aircraft hangars and multipurpose halls.

Zamil Steel has a long list of local and international customers including some of the largest global manufacturers and contractors, such as Toyota, Honda, Nestle, Coca-Cola, Proctor & Gamble, Fuji, Fujitsu, BP, Chevron, Saudi Aramco, the Royal Commission of Jubail and Yanbu, Al Hokair, JGC, IHI, Mitsui, Mitsubishi, Daewoo, Hyundai, LG, Bechtel, Chiyoda Corporation, Toyo Engineering, Technip, Techint, Snamprogetti, ABB, SEC, STC, Etihad, Etisalat and Emirates Electrical.

To serve a market that now covers the far reaches of the globe, the company has been expanding its factory network. In April last year, Zamil Steel officially inaugurated its second production facility in Vietnam, at the Amata Industrial Park near Ho Chi Minh City in southern Dong Nai province. The SR75-million ($20-million) factory boasts a monthly production capacity of 4,500 tonnes of PEBs and other steel products. This facility has allowed Zamil Steel Vietnam to increase its total production from 50,000 to 100,000 tonnes of PEB annually.

New production facilities were also set up in Pune, India, in November last year. This state-of-the-art manufacturing facility, built over 87,000 sq m, is capable of producing 30,000 tonnes of PEB and other steel products annually. The total investment in Zamil Steel India is approximately SR120 million ($32 million).

Meanwhile, a new sandwich panel has been set up in the second industrial city in Dammam and began production recently.

Despite the global slump in business, 2008 was a good year for Zamil Steel, with the PEB giant recording its best-ever physical and financial performance through its continued emphasis on higher production. “Our consolidated production in 2008 reached 450,000 tonnes, which is an increase of 18 per cent over 2007. Our exports increased by 20 per cent over 2007,” says Turki.

He continues: “Certainly, the market has shrunk due to the recession and so we have adapted our production to suit the current reduced demand, but without diminishing our capabilities to expand and return to full speed once markets recover. We are optimistic of our performance over the coming year compared to similar industries under the same circumstances. This stems out of our organisation’s strength and strategic depth as an international player.”

Zamil Steel was established in 1977 to design, manufacture and supply PEBs. Its main factories are based in Dammam over a site area of 518,000 sq m. Additional factories are located in Egypt, Vietnam, the UAE and India. More than 600 engineers are employed in its engineering departments in Saudi Arabia, Jordan, Egypt, Vietnam and India – part of a total of strength of 3,190 employees. In addition, the company has 56 area offices in 50 countries, besides engaging the services of a wide network of certified builders around the globe. It also exports to about 85 countries worldwide.

As an industry leader, Zamil Steel excels in engineering, manufacturing, sales and project management and offers clients a diverse range of products from which to compile a total building solution. The company utilises state-of-the-art engineering and manufacturing software and machinery in the design, estimating, shop detailing and manufacturing of each of its products. Zamil Steel is one of the diverse sector businesses of Zamil Industrial Investment Company (Zamil Industrial), and its flagship, the other major sectors being Zamil Air Conditioners, Zamil Glass Industries, Arabian Fiberglass Insulation Company (Afico), Ranco & Zamil Precast Concrete Industry and Acico for aerated concrete products.

.jpg)

.jpg)

Doka (2).jpg)

.jpg)

.jpg)

.jpg)