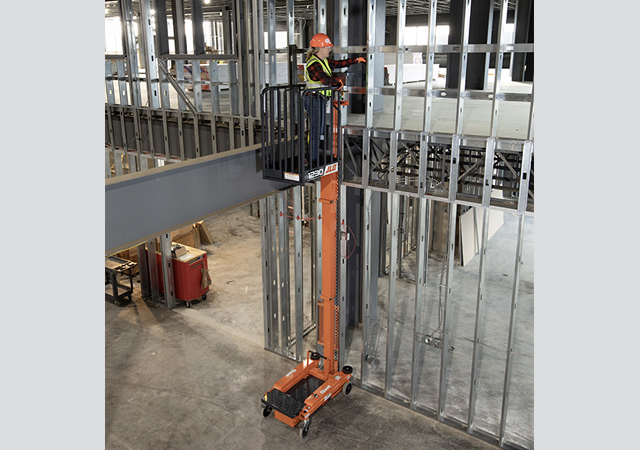

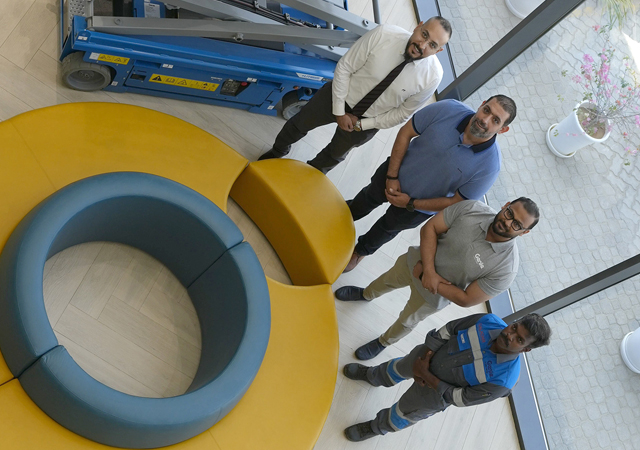

Pervaiz ... privilege to work at Future Ceramics.

Pervaiz ... privilege to work at Future Ceramics.

AJ CORPORATION (AJC), a Pakistan-headquartered multidiscipline engineering specialist, is responsible for fabricating and installing some of the advanced equipment including carbon steel and stainless steel piping network that will ensure efficiency of operations at Future Ceramics’ factory.

The task involves detailed engineering, procurements, fabrication, sand blast painting and installation of some 2,000 tonnes of equipment at the plant. AJC’s role in the project started in August last year.

Muhammad Akmal Pervaiz, AJC’s executive director, says: “It is a privilege to be working with such a prominent business group and on one of the largest ceramic plants in the region. The significant challenge has been to meet the satisfaction of our client and Sacmi of Italy, in terms of quality, professionalism and completion schedule, among other aspects. We have achieved this goal, thanks to our top project management team and quality control systems.”

The project involved total fabrication and installation, including detail engineering of process metal bins for the ceramic plant.

“This is one of the high elevated equipment and the total weight of this system alone is more than 100 tonnes. These adjacent bins have been completely coated with layers of chlorinated rubber,” he explains.

It also included similar work on an LB Italy-designed technological tower along with all process hoppers and silos made out of stainless steel. This tower, weighing about 300 tonnes, is located in the porcelain plant.

Other works included setting up stainless steel tanks at the glaze department and its operational and support platform structural systems along with its stainless steel piping network, carbon steel and stainless steel (CS/SS) process piping network for compressed air, water and chemicals, kiln and dryer chimneys, dense colour tanks and platform systems, zirconium silo and its support structure, atomiser (ATM) slip feeding tanks and platform, a turbo crusher platform, and belt conveyors hoods and connections. Ball mill feeding silos, raw material and pre-grinding loading hopper systems for both the ceramic and porcelain plants are also part of AJC’s scope.

Work also included detail engineering, fabrication and installation of a complete range of belt conveyor’s bridges and platform structures for both the porcelain and ceramic plants for areas such as pre-grinding, raw material feeding and loading, ball mill feeding systems; modular mill continues (MMC) structure and monorail systems; mill tamburo discontinue (MTD) service platforms; a multi-storey belt conveyor support structure system for feeding to process bins; vibrating screen structure; and presses service platform.

AJC’s Saudi operations, established in 2006, offers a wide range of services, including design and detail engineering; on-site fabrication and installation of CS/SS/alloy steel silos, vessels, bulk storage tanks, piping, heavy structures, hoppers and conveyor structures among other structures, supported by fully-controlled and systematic quality control checks; installation of plant machinery and equipment; heavy and elevated erection works with rigging facilities; sand blasting and painting; cross-country pipeline installation; plant maintenance; plant dismantling, transportation and re-installation; civil foundations; and project management.

One of its striking facilities is a mobile/portable heavy fabrication workshop, which is fully equipped with state-of-the-art machinery such as sheet rolling, sheet bending, hydraulic presses, heavy-duty compressors, plasma cutting machine, GMAW/SMAW/GTAW/FCAW welding equipment, sandblasting and painting machines and 800-kVA power generators. The workshop is completely run on its self-power-generating systems. AJC sets up it workshop at client’s premises and all the fabrication works can be closely monitored by the client despite AJC having its own QA/QC systems.

“This facility gives clients the assurance of AJC’s ability to meet their hi-tech requirements as they are able to inspect its work at their premises. This apart, transportation time is saved, apart from costs,” he says.

AJC’s other major clients include Saudi Aramco and private customers. Recently, it has been involved with Royal Saudi Navy Special Forces to construct its obstacle course training complex.

“As AJC is a mechanical company, the contract was unusual for us as the entire project involved high–quality woodwork along with civil foundation on a sandy area on the coast. However, the job was completed satisfactorily,” says Pervaiz.

He sees a bright future for the company in the Saudi market. “AJC’s business curve has been on the rise, thanks to the hard work put in by the entire management team and our efficient systems. We have been receiving an excellent response from the Saudi market, with several private firms approaching us for their projects. This can be attributed to the fact that we offer reasonable prices, high quality work and a highly efficient management system. Our policy is to maintain realistic profit margins so as to remain competitive in the market,” says Pervaiz.

This is the reason why AJC has been able to evade the effects of global recession. The company now plans to expand its business across the kingdom.

A J Corporation Pakistan was set up in 1980. It has offices in Dammam, Karachi and Lahore employing 200 staff, besides having its own warehousing and camping facilities. The company has facilities for designing and detail engineering (using the latest software) of processing tanks, vessels, process piping, steel structural buildings and equipment. Project management services are also provided.

AJC has gained a reputation in the field of design and construction of bulk oil storage tanks and is equipped with the girth welding facilities. It serves a wide number of industrial sectors in Saudi Arabia and the region, including ceramics, chemicals, petrochemicals, oil and gas, fertilisers, cement, air separation and industrial gas plants, power plants, infrastructure, industrial alcohol and distilleries, the sugar, edible oil and ghee industry, paper and packaging industry, lubricant industry, effluent treatment plants for solid waste, reverse osmosis plants, steel industry and DRI (direct reduction iron) plants, bulk oil storage tanks and terminals, pre-engineered buildings, and food and dairy industries.

In Pakistan, AJ Corporation recently handed over one of its biggest projects, the Al Moeez Sugar Mills, and is currently working at a project with National Refinery.

.jpg)

.jpg)

Doka (2).jpg)

.jpg)

.jpg)

.jpg)