Xlife and Staxo 40 ... revolutionary systems from Doka.

Xlife and Staxo 40 ... revolutionary systems from Doka.

DOKA once again asserts itself as a formwork leader that provides solutions for “tomorrow’s challenges” with its new ‘revolutionary’ load-bearing tower and innovative systems to facilitate forming of floor-slabs. These products are designed to cut down equipment costs and set a new benchmark in ergonomic design and safety on site, says the Austria-headquartered company.

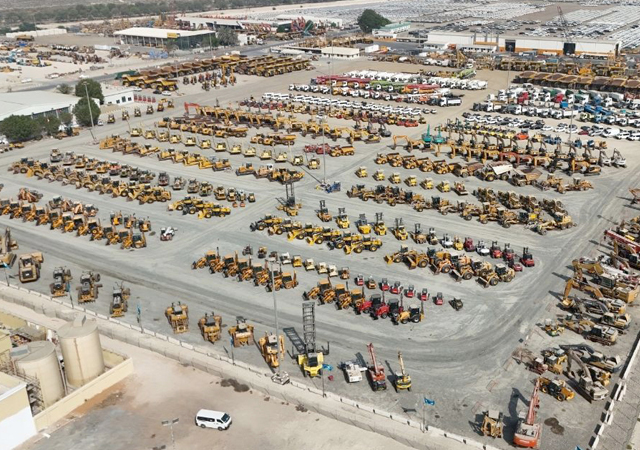

The Staxo 40 load-bearing tower, the DoKart trolley and a self-climbing table lifting system – which will be among the innovations showcased by Doka at bauma 2010 next month (April 19 to 25) in Germany – are expected to be offered to the Qatar market by the company’s branch office in the country.

|

Staxo 40 load-bearing tower is designed to ease work and enhance safety on the construction site.

Elaborating on its advantages, a company spokesman explains: “For shoring tasks in the building construction field, it is common to use load-bearing towers based on single legs. However, serious delays and safety risks are encountered when this type of shoring tower is erected and dismantled. After analysing these shortcomings, Doka devised a revolutionary load-bearing tower based on a frame system – so revolutionary, in fact, that it redefines the norm for ergonomic design and speed of work.”

The unique H-shaped frame geometry of Staxo 40 makes it possible, for the first time, to have barrier-free workplace access routes and work-deck levels extending across several scaffold units at once, the spokesman says, adding that this makes working beneath the tower frame superstructure much easier, quicker and safer.

He continues: “Doka’s development engineers have also been successful in greatly reducing the dead weight of the Staxo 40 frames while retaining their high stability and load-bearing capacity. To adapt to different heights, the tower gets by with just three different sizes of frame. Additional last-millimetre adjustability is provided by screw-jack heads and feet with a total extension length of 140 cm.

|

|

The Doka Table Lifting System … already successfully utilised in Qatar at Al Rames Tower. |

Innovations

Meanwhile Doka – already a world leader when it comes to fast, safe working with tableforms – is now setting new benchmarks with the DoKart and the Table Lifting System (TLS). “With these innovations, the company has pulled off a trick that even experts had reckoned was just about impossible: speeding up the repositioning of tableforms even further, with even greater safety, and completely independently of the site crane,” the spokesman states.

The new DoKart is described as being ideal for positioning tableforms on the same level. “Doka has re-invented the shifting trolley, giving it just what it takes to cope with the rough-and-tumble of work on the site. One-man operation had always been the norm at Doka and the DoKart is no exception,” adds the spokesman.

The trolley is robustly built for long life and high reliability, with large wheels that give it generous ground clearance and allow it to move around typical building-site floors safely and unhindered. “Its high lifting speed is equally revolutionary. A quick push of the button, and the tableform is adjusted back up to the right height for forming, in just a couple of seconds,” he says.

Meanwhile, for transporting floor-slab formwork up to the next storey, Doka offers the TLS, an innovative lifting platform that whisks a tableform up to the next floor in only 20 seconds, the spokesman claims.

He continues: “Once all the tableforms have been moved up from one floor to the next, the TLS itself also needs to be repositioned. Until recently, this was always done using a crane. Now a new, self-climbing version of the TLS makes it possible to form floor-slabs totally without the use of a crane, while enhancing safety during the lifting operation.

“This makes the self-climbing TLS particularly suitable for use on tall buildings. As it is structure-guided at all times, the self-climbing TLS can be safely raised even in poor weather conditions.

“When used in conjunction with the protection screen Xclimb60, this new solution is simply ideal, as both the protection screen and the TLS are ‘climbed’ up to the next casting section using the same technical system. Alternatively, where sufficient craneage is available, the TLS can also be raised by crane, guided on the structure in this case as well. Doka site foremen are available to assist with advice and practical help when it comes to erecting the TLS on-site and training the site crew.”

Products upgrade

The formwork manufacturer, meanwhile, continues to upgrade its existing portfolio to enable its customers to constantly benefit from the high utility and cost-efficiency of its latest formwork technology. One such product is the Xlife sheet, which boasts the advantages of excellent durability and quicker and easier cleaning, now also available in the lightweight framed formwork Frami Xlife. This upgrade to the timber-plastic composite Xlife sheet, which also has special tie-hole protectors, hugely extends the service intervals between changing sheets, the spokesman says.

“What is more, the special surface structure ensures the very best concrete results even after many, many repeat uses. On rented formwork, Xlife cuts the close-out costs for reconditioning damaged form-facing, and reduces the amount of finishing-work needed on the concrete,” he says. “Frami Xlife is the highly cost-efficient solution for walls, column and foundations.”

Doka Qatar will be offering its clients the comprehensive portfolio of pathbreaking innovations that are to be introduced and showcased at the bauma 2010 trade fair. “The experience the company has gained with local contractors shows that the market is willing to draw benefits from Doka’s experience and latest product developments,” says Jenoe Rulff, general manager of Doka Qatar.

“Whether it is building construction or civil engineering projects,” he says, “Doka formwork systems always guarantee high cost-effectiveness combined with the highest safety standards. Doka’s branch in Qatar has, therefore, been able to establish itself as a competent and capable formwork partner for the construction industry and plans to expand its leading market position in all sectors of construction.”

Rulff emphasises that the Qatar branch will continue to exert efforts to ensure that the company’s growth is sustained by identifying new opportunities and optimising the formwork offer.

“The market launch of the new products will open up a new potential for Doka Qatar, and the company is intent on making full use of the opportunities this offers,” he concludes.