Metal ceilings ... offered in a wide range of standard as well as custom patterns.

Metal ceilings ... offered in a wide range of standard as well as custom patterns.

USG Boral ME, a renowned manufacturer of finishing products, has begun production of metal ceiling panels in its Dammam factory in Saudi Arabia. The move marks a major expansion of the company’s product portfolio which includes plasterboard, compounds, ceiling lining systems and accessories.

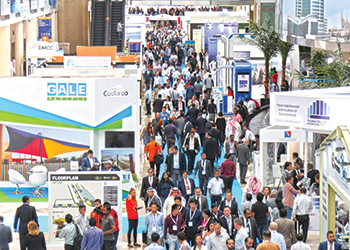

The new product range, an extension to the USG Boral ME’s ceiling tiles portfolio and manufactured according to ASTM standards, will be revealed in the region at The Big 5 show in Dubai, UAE, this month (November).

“USG Boral ME’s metal ceiling systems offer a world of possibilities,” says Fares Saghbini, managing director of USG Boral ME, which has its headquarters and production plants in Dammam.

Commenting on its latest manufacturing venture, Saghbini says USG Boral ME’s move is aimed at meeting the growing demand for metal ceilings in the region.

To offer an alternative system for projects such as airports, hospitals and universities, USG Boral ME has invested in a fully automated multiline offering a wide range of high quality aluminium alloy and metal ceiling systems. This multiline can cater to all sizes and shapes, with a specialty line for odd sizes and perforations including CNC (computerised numerical controlled) machines. These tiles are electrostatically powder coated in-house using premium products.

“The USG Boral portfolio combines aesthetics, durability and performance. It also offers unique systems, providing the specifier with unlimited design possibilities for applications ranging from banks to corporate offices, and from airports to shopping malls.”

|

|

Metal ceilings ... offered in a wide range of standard as well as custom patterns. |

These superior quality products are available as standard suspended ceiling systems such as exposed grid or concealed suspension systems as well as custom-made metal ceilings to meet the various requirements of architect’s specifications.

USG Boral systems come in a wide range of standard as well as custom patterns that are durable and have a washable polyester powder finish. The tiles are press formed from aluminium alloy series 3000 or mild steel and factory-finished with an electrostatically applied polyester powder coat (70 to 90 microns) while suspension components are made from galvanised steel and pre-painted steel or aluminium. Panel thickness ranges from 0.5 to 1.4 mm.

The systems have high sound absorption and sound attenuation and are environment-friendly and recyclable. In addition, an extensive range of perimeter options is available. The ceiling systems offer easy access for service maintenance, and are robust and easy to clean, Saghbini points out.

The Lay-In and Lay-On Ceiling is a demountable system, suitable for commercial, retail and display areas. It has been designed for an exposed grid suspension system – either DX, DXT or Omega grid – to form flush or Tegular suspended metal ceilings. The system, which is easy to install, provides a strong modular or flush appearance. It is available in a range of module sizes and features sealed-in acoustic infills.

The ceiling tiles are square or rectangular with formed edges to rest on the flanges of the grid system. These can be simply lifted out of the suspension system to gain access to the ceiling plenum.

The Clip-In Ceiling panels may be supplied either plain or in a range of perforation patterns with a nominal 11-mm plain border.

Both the Clip-In and Lay-In types meet several industry standards including ASTM E119 for fire tests of building construction and materials; ASTM C423-99 for test method for sound absorption and sound absorption coefficients by the reverberation room method; and ASTM E84 for fire hazard classification, among others.

|

|

The metal ceilings are manufactured to ASTM standards. |

The standard colour of the panels is a special USG Boral white with 20 per cent gloss; while alternative colours according to classic RAL are available as well.

USG Boral’s ceiling panels are available with high recycled content (HRC), that is, classified as containing up to 90 per cent of total recycled content.

The panels have excellent acoustical performance quality – noise reduction coefficient (NRC) and ceiling attenuation class (CAC). “Through appropriate selection of perforation pattern and acoustic infill, it is possible to improve speech intelligibility, reduce unwanted noise and increase privacy within the space or between adjacent offices,” says Saghbini. “Perforated ceiling tiles with an acoustic back fleece overlay or mineral wool pad absorb sound energy and serve to control acoustic reverberation time. Different combinations of perforated open areas and acoustic pad density/thickness provide different levels of sound absorption.”

For sound attenuation features, USG Boral ceiling panels can be manufactured with a range of mineral wool acoustic infill.

In addition to these features, the Lay-In panels are in full compliance with ASTM C636 and with ASTM E580 for seismic performance and can be produced to meet class A fire rating upon request.

USG Boral was formed in 2014 when Boral (Australia) and USG Corp (US) joined forces to deliver a portfolio of building products which includes plasterboard walls, compounds, ceiling lining systems and accessories across Asia, Australasia and the Middle East. USG Boral offers the region a locally made system with international warrantees, backed by a team of professionals available round the clock to provide support to customers, right from the early stages of design up to the hand-over of a project, says Saghbini. Its Middle East manufacturing operations for mineral fibre, laminated ceilings, drywall partition systems (stud and track), Donn DX brand suspension systems and Sheetrock brand joint treatment products are based at Dammam.

USG Boral will be at Stand 8C357.

.jpg)

.jpg)

.jpg)