The transport of water in buildings is one of Geberit's core competences. The company ensures high standards of hygiene and economical use of resources, thus making a key contribution to ecologically sustainable development.

Water is a precious resource. Global warming means that it is already in short supply in many regions of the world. Careful use of water, especially drinking water, is therefore of the utmost importance.

Saving water with Geberit

The careful and economical use of water as a resource is a key topic for Geberit. The consistent focus on reducing water consumption in both the production and product use phases represents the company's greatest lever for sustainable development.

Geberit has a long tradition of manufacturing water-saving products, especially WC cisterns and their components.

One third of water consumption

Flushing the toilet accounts for around a third of a household's daily water consumption.

• In a Swiss household, 29% of daily water consumption is due to flushing the toilet. A further 25% is used for showering or bathing. 1

• In a German household, 27% of daily water consumption is used for flushing the toilet. A further 36% is used for bathing, showering and personal hygiene.2

This means that an enormous amount of water can be saved with WC flushes. This is why Geberit is constantly developing the water efficiency of its toilet systems, with quantifiable results.

.jpg) |

|

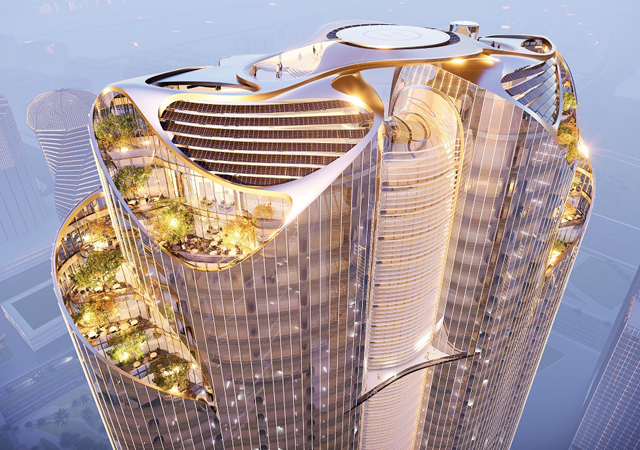

Geberit Acanto … the entire water path from the cistern via the toilet to the drain has been optimised. |

Three factors play a key role here:

• Flushing performance: Geberit’s efficient and resource-saving flushing systems are centred around function, i.e. the optimal flushing of the toilet. If it is enough to flush once to keep the toilet clean, a lot of water is already saved – on average six litres per flush. This is why Geberit concentrates on developing products that guarantee optimum flushing performance while minimising the amount of water used.

• WC ceramic appliances: When the water flow from the cistern enters the WC, it hits the ceramic appliance. The internal geometry of the ceramic appliance is decisive for the water efficiency of the flushing process. If the water flow is channelled efficiently through the toilet bowl, smaller amounts of water are required to flush the toilet clean. The WC ceramic appliance, therefore, accounts for a significant proportion of the water-saving potential of the Geberit WC system.

• Flushing technology (dual flush, cistern and flush valve): Older toilets require up to 14 litres of water per flush. Converting to a stop-and-go flush or dual-flush system can save a considerable amount of water compared to a single flush. With Geberit flush valves, the amount of water for the large and small flush can be set in stages (flush valve type 212: six stages for the large flush from 4 to 7.5 litres, 11 stages for the small flush from 2 to 4 litres).

The Geberit Acanto WC system is a good example of water efficiency in the bathroom. The entire water path from the cistern via the toilet to the drain has been optimised. This means that the toilet is optimally flushed out even with small amounts of water. When the TurboFlush flush technology of the Acanto WC ceramic appliance is combined with the water-saving flush valve 212 and dual flush technology, the flush volume required is reduced to 2.6 litres for a partial flush and 4 litres for a full flush - exceeding the flush performance required by European standards by up to 10 times. With a Geberit WC system, the toilet is entirely clean after just one flush.

Various factors contribute to this performance: The asymmetrical inner geometry of the WC ensures that the flush water is directed through the ceramic in a powerful vortex. Conventional WC ceramics often have an area in the middle of the swirling eddy current that remains motionless (similar to the eye of a whirlwind), allowing lighter residues like toilet paper to get caught. The Geberit WC system uses the momentum of the water to move the centre of the vortex and ensure the trap is flushed out completely.

Thanks to such innovations, it is now possible to use just 14 litres per person per day for flushing. According to a model calculation, water consumption for flushing the toilet has been reduced by around 80% compared to 1952 – from an average of 70 litres to 14 litres per person per day.

Water-efficient urinal systems

In public and semi-public areas, Geberit urinals with electronic flush control offer optimum flushing with a minimum water volume of 0.5 litres. Completely waterless urinals are also available. Thanks to a thin membrane in the trap, the liquid can drain away without bad odours escaping from the drainage pipes.

Geberit has developed a calculator to show customers the environmental impact, water consumption and costs of the various urinal systems.

Electronically controlled tap

The use of electronically controlled taps can reduce water consumption by over 50% compared to conventional taps. Wall-mounted taps are easier and quicker to clean than deck-mounted taps, which further reduces the consumption of water and cleaning agents. In order to optimally adjust the amount of water to the legal requirements and individual customer needs, Geberit offers various tap aerators that can be used to optimise water consumption.

Geberit ONE wall-mounted tap

Geberit offers the Geberit ONE wall-mounted tap for the private sector. It has a water-saving tap aerator with a maximum flow rate of 5 litres per minute (l/min) – which is not exceeded even at higher flow pressures – thus ensuring this washbasin tap offers a very good combination of water saving and comfort. Thanks to separate operating levers, the flow rate can be conveniently adjusted without affecting water temperature.

Saving water and building labels

With its innovative sanitary solutions, Geberit has established itself as a reliable partner for sustainable construction. Its solutions in the area of water efficiency contribute to sustainable construction and can help to obtain a sustainability certificate for a building.

Building labels generally ensure transparency and make it possible to compare buildings. There are now many different sustainability labels and among them three organisations and their certificates have become particularly established internationally: LEED, BREEAM and DGNB. Depending on the market, other national labels are added, such as Minergie (CH), HQE (FR), WELL, Nabers or Green Stars.

Generally, the certification of a building is based on a comprehensive catalogue of criteria. Water efficiency is only one of the criteria assessed and its relevance varies depending on the label. The water consumption criterion assesses how much water users consume. With regard to water consumption in the bathroom, the installed flushing systems and the calculated average flush volumes are primarily taken into account. Compliance with the international standards EN14055 for cisterns and EN997 for toilet bowls is decisive. All Geberit products relevant to this criterion fulfil both standards. With regard to the calculated flush volumes, the company’s flushing systems which require just 4 litres for the full flush receive the maximum number of points for the LEED and BREEAM labels.3

The Geberit Monolith sanitary module receives the second-highest number of points for this criterion due to its reduced flush volume range from 4.5 litres. Geberit WC ceramics also receive the highest and second-highest number of points for the LEED and BREEAM labels. Here too, the minimum calculated full volume with which the toilet is optimally flushed is decisive. Rimfree WC ceramics by Geberit receive the highest score.4 Geberit ceramics with a flush rim score the second-highest number of points. In the case of combined products – flushing system and WC ceramic appliance – the score of the lower-rated product is decisive.

The German Sustainable Building Council (DGNB) has its own set of criteria for water efficiency, which might have a narrower range of acceptable flush volumes compared to LEED and BREEAM. Geberit's products still meet these DGNB requirements.

Historical development: working to save water

As early as the 1970s, the topic of water came into focus. Geberit developed water-saving solutions for the bathroom on its own initiative and campaigned for the careful use of water. The company even declared war on prevailing norms.

In 1970, for example, the standard for sanitary technology in Germany stipulated that a toilet must be flushed with at least nine litres of water. Products that did not meet this standard were not approved. Geberit went to great lengths to dissuade the experts from this requirement: “Nine litres of flush water is too much! Both for economic reasons and for the need to use drinking water sparingly for the sake of the environment,” the company wrote at the time.

Geberit’s voice was heard: in the 1980s, the company received approval for toilet cisterns with a stop button in the southern German state of Baden-Württemberg. Shortly afterwards, they were approved throughout the rest of Germany. This led to the proliferation of toilet flushes with a stop button that only required six litres of water. Thanks to Geberit’s preparatory work, the rules for toilet flushes were also changed in Switzerland and China, for example, in order to reduce water consumption.

Find out more on the 150th anniversary website

Eco-design and the new WC system

Since 2007, all new products at Geberit have been consistently developed according to the eco-design principle. This also includes the Acanto WC system, which is installed on the Duofix installation frame. Ecological data for both sanitary ceramics and Duofix are shown transparently in an Environmental Product Declaration (EPD). The combination of innovative TurboFlush flush technology and flush valve 212 ensures that even small quantities of water of 2.6 litres (partial flush) and 4 litres (full flush) are sufficient to completely flush out the WC bowl. Flushing is triggered by the recyclable Sigma30 actuator plate made of plastic, which is mounted in a frame made of 100% recycled ABS plastic. All products are characterised by their durability. They can be repaired even after many years of use. Geberit ensures the availability of spare parts for concealed cisterns, such as flush or fill valves, for 50 years.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)