.jpg) Firetrace systems ... installed at the Imam Muhammad bin Saud Islamic University in Riyadh.

Firetrace systems ... installed at the Imam Muhammad bin Saud Islamic University in Riyadh.

The XM PFP and Xtreme PFP (top right) sprayers and XHF high-flow spray gun (right).IN recent months, Firetrace tube-based systems have been installed to protect a host of business-critical micro-environments throughout the Gulf.

These include school bus engine compartments, motor control cabinets, dockside crane engine compartments and electrical cabinets, portable generators on offshore rigs, server cabinets and sub-floor voids. Major projects have been completed in Abu Dhabi, Dubai and Ras Al Khaimah in the UAE, Saudi Arabia and Qatar.

.jpg) |

A bus engine compartment. |

This success has, in part at least, been driven by the recent spate of fires across the region – including shopping mall fires in Qatar and Dubai – that has resulted in local authorities, such as civil defence, looking more closely at solution providers and insisting on internationally approved systems.

Authorities across the region are also now placing greater importance on protecting their country’s critical infrastructure. Additionally, forward-looking companies in the region have realised that business continuity and the protection of business-critical assets are essential drivers of success, and that Firetrace is a key element in achieving both objectives.

While Firetrace solutions have been prominent throughout the Gulf for several years, the establishment of a dedicated Gulf-based operation, Firetrace International (Middle East), towards the end of 2010 undoubtedly also had a major impact on the market’s accelerated take-up of the systems. By setting up a permanent presence in the region with dedicated sales, operational and technical resources, Firetrace International demonstrated its lasting commitment to the region’s market.

.jpg) |

Electrical cabinet. |

Project round-up

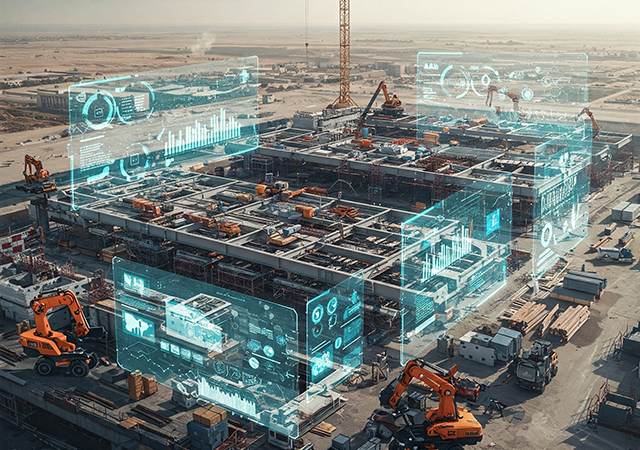

The result is that the order book now boasts orders that include 800 Firetrace systems destined for Lusail – a new city taking shape in Qatar – and other various sites in Qatar protecting electrical motor control cabinets for sewage and drainage plants. This is the largest single order ever placed with the company. A further 1,000 Firetrace systems are destined for a Saudi Binladin Group (SBG) project. In addition, orders for the new Firetrace Total Flooding system have come from Saudi Arabia and Qatar.

Firetrace International has been supplying Firetrace systems for the past three or four years for drainage and sewerage projects in Qatar, with the latest order bringing the 2012 total to 970. In this instance, the chosen suppression agent was DuPont FM-200. The same suppression agent was chosen for the SBG project to protect essential motor control cabinets for the Grand Mosque extension project in Makkah, Saudi Arabia.

.jpg) |

Firetrace cylinders and the system illustrated (below). |

However, not all of the recent Firetrace installations are safeguarding fixed installations. Firetrace International has also supplied several of its tube-based systems to protect the engine compartments of cranes at Saqr Port in Ras Al Khaimah in the UAE, following a costly and disruptive fire. The installations proved so effective and reliable that a further 20 systems have now been supplied for new cranes at the port.

For these engine compartment applications, ABC dry chemical powder was identified as the most appropriate agent. Following discharge, it leaves a residue that absorbs flammable liquids, helping to avoid re-ignition. The particles of powder are too large to penetrate engine air filters and so the exposed external engine surfaces will need only to be cleaned after a system discharge, by wiping, vacuuming, or washing.

.jpg) |

Similar Firetrace systems are protecting the engine compartments of Ashok Leyland-built school buses in Dubai, again using ABC dry powder as the appropriate suppression agent. The decision to install Firetrace systems was taken after the Dubai authorities mandated that fire suppression system be fitted to all school buses in the emirate. The supply of these systems is now in its third or fourth year and 60 systems are expected to be installed this year.

Tube-based solution

But how does the tube-based Firetrace system achieve such success? In short, it is a combination of engineering ingenuity, reliability and effectiveness. Despite the 150,000 completed installations, there has never been a single instance where a properly installed and maintained Firetrace system has either failed to detect and suppress a real fire or false alarmed. Every Firetrace system provides intrinsically safe, around-the-clock protection that requires no external power or human intervention.

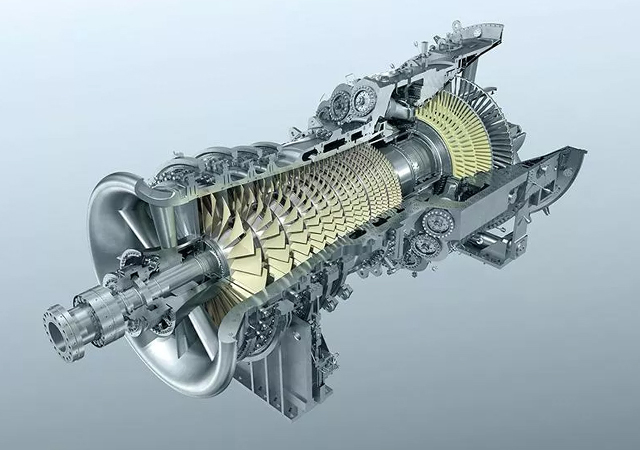

Each system comprises a cylinder that contains the chosen suppression agent, which is attached to technically-advanced proprietary Firetrace detection tubing. This leak-resistant polymer tubing is a linear pneumatic heat and flame detector that consistently delivers the required temperature-sensitive detection and delivery characteristics. It can be routed throughout the enclosure being protected and when it is exposed to heat and radiant energy from a fire, the tubing ruptures and the suppression agent is instantly discharged. The fire is extinguished in seconds, precisely where it starts and before it has had time to take hold.

Full room protection

While remaining committed to the principle that the majority of business-critical assets are most cost efficiently and effectively safeguarded by providing them with dedicated in-cabinet protection, Firetrace International’s Engineered System enables the company to provide customers around the world with a single source of supply for mission-critical asset protection, whatever the shape or size of the area being protected. This recognises that there are some applications that may be best protected by a total flooding system.

.jpg) |

New Firetrace tubing ... technically advanced detection system. |

End-users benefit from a much lower financial outlay when compared with similar systems on the market, significantly improved design freedom, and a swift, least-cost transition from an existing halon system to the latest clean agent technology and delivery solution. When using 3M Novec 1230 fire protection fluid as the suppression agent, the Firetrace Engineered System also offers the benefit of 500 psi (34.5 bar) high-pressure efficiency while utilising low pressure hardware, drastically slashing the amount of piping used.

Sustainability

So, both the Firetrace in-cabinet systems and the new Engineered System provide an opportunity for end-users to embrace sustainability and minimal environmental impact, thanks to the use of the latest clean agent technology – 3M Novec 1230 fire protection fluid and DuPont FM- 200. Both are non-corrosive and non-conductive agents that are listed in appropriate codes and standards such as NFPA 2001:2012 and BS EN 15004:2008.

BIG.jpg)

.jpg)

.jpg)