PASSIVE and active fire protection systems are both necessary to ensure the integrity of buildings and play a complementary role in preventing human and material loss in the event of a fire, says Isam Kabbani Group (IKK), a well-diversified Saudi group.

In its endeavour to become the world leader in construction and contracting, IKK is sparing no efforts in keeping pace with latest developments in fire protection and safety in a world where the focus is increasingly on protective lives and preventing material loss.

The company has years of experience in the fire protection sector and is looking to increase the awareness and use of such systems – and particularly passive fire protection systems.

“Fires can cause major disasters with loss of life and property. Therefore, buildings need to be proper protected,” says a spokesman for the Jeddah-headquartered company. “Statistics show that 30 per cent of disasters are caused by fires, and 16 per cent of all the victims of accidents and disaster are due to fires.”

“Hence countries all over the world are giving high priority to fire protection measures with safety and loss prevention having become a primary goal in project specifications,” the spokesman adds.

Special associations such as NFPA (National Fire Protection Association), ASFP (the Association for Specialist Fire Protection) and SFPE (Society of Fire Protection Engineers) supported by the Underwriters Laboratories and ISO International Organization for Standardization, provide important guidelines on ensuring fire safety.

Types of fires

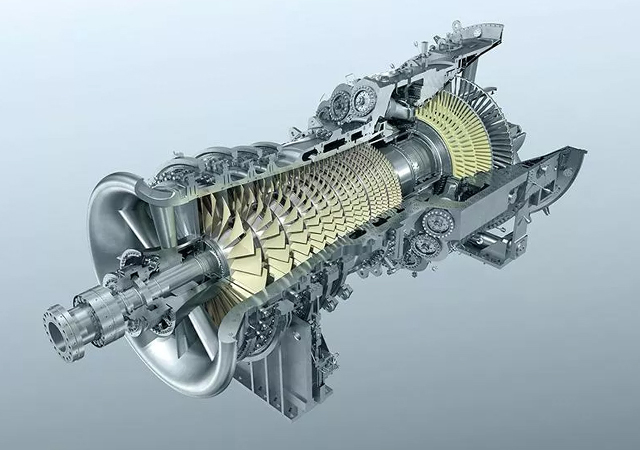

Fires are categorised as hydrocarbon and cellulosic, based on the time taken to reach the maximum temperature when structural elements begin to collapse. Under simulated conditions in laboratories, it has been determined that a hydrocarbon fire reaches 900 deg C in eight minutes, while a cellulosic fire takes 60 minutes, he says.

Hydrocarbon fire that occurs in refineries, gas plants and power stations depend mainly on oil and gas and derivatives to fuel the fire. On the other hand, fire in high-rise buildings, towers, shopping malls and universities rely on components such as wood and paper to sustain it.

In terms of building protection, fire detection and prevention depends primarily on passive and active fire protection systems.

An active fire protection system responds to elements such as heat, smoke and light to extinguish the fire using water spray, dry powders or foams systems installed in place or portable. “Despite their obvious benefits, such systems do have their drawbacks: they may lose effectiveness as their components such as pipes and valves could get corroded or be damaged over time – or the system itself may not be able to perform in the event of a power outage,” says the spokesman. “Therefore, it is unwise to rely solely on active fire protection as a single system that is not guaranteed to work properly and provide full and permanent protection to the building.”

On the other hand, passive fire protection systems safeguard a building in a fire by delaying the meltdown of metal and composite structural elements (metal elements begin to lose their mechanical properties in temperatures of 550 to 620 deg C) or cracks in concrete elements – which lead to the collapse of the building – by up to four hours, which is long enough to evacuate occupants of the facility, and allow firefighters and rescue teams to get to work.

Both passive and active fire protection systems should, therefore, be integrated and work in parallel, as stipulated in guidelines for fire protection systems.

“Given that statistics and studies have shown that 60 per cent of deaths in a fire are not due to the fire itself but because of suffocation, we recognise the importance of fire-proof materials as key to minimising the loss of lives,” says the spokesman.

Fireproof materials

However, although fire-proof materials are easy to apply or install, this must be undertaken by skilled workers who are well-trained and licensed by the manufacturers and under the supervision of licensed professional engineers, he says.

Fireproof and blast-resistant panels play a key role in fire protection as indicated by studies on loss prevention in oil or petrochemical facilities, which have highlighted advantages of these panels particularly in hazardous zones.

Also, fire-retardant materials should be used in data centres and communications chambers in sensitive facilities in particular and in areas that make extensive use of wood such as hotels, universities and hospitals as they delay combustion. Other utility elements of the building, such as pipes, electric cables, metal stands, central air-conditioning ducts and elevators have their own regulations and codes regarding use of fire protection and materials including fireproof and non-combustible panels.

In Saudi Arabia, the civil defence authorities last year made it mandatory for all multi-storey buildings to conform to passive fire protection requirements while meeting the specifications currently set for active fire protection.

IKK’s role

IKK has also been playing a proactive role in this by increasing its focus on this sector. “In line with these instructions, we have given great importance to these applications and have plans to expand the use of these materials and to raise awareness of the importance of such applications in various engineering structures. We have also an independent technological centre for engineering consultation for all aspects of fire,” the spokesman says.

The company has years of experience in the fire protection sector, having set up a dedicated department – Fire Proofing Unit (FPU) – a number of years ago to provide the entire gamut of engineering services for contractors and consultants alike, through a professional team of skilled technicians under the supervision of qualified engineers, backed by high quality products for which IKK has gained a reputation.

The FPU’s scope of works includes fire-proofing, starting from low-density cementitious material to intumescent paints, fire-proof and blast-resistant boards, systems to fire stop materials and fire retardants.

“Maintaining public safety and fire protection go hand in hand to meet in one goal – to protect lives and prevent losses. Due to the difficulty and even impossibility to test materials after they are applied on structural elements, high quality and professionalism in the actual installation of fire protection systems is the only way to guarantee that these materials conform to international standards and specifications,” the spokesman concludes.

BIG.jpg)

.jpg)

.jpg)

.jpg)