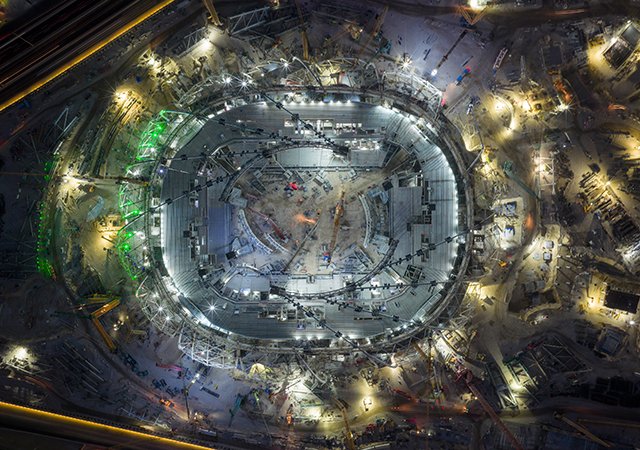

Work on the stadium has evolved into a round-the-clock effort, with teams engaged in shifts in welding, heavy machinery operations, and installation of structural components.

Work on the stadium has evolved into a round-the-clock effort, with teams engaged in shifts in welding, heavy machinery operations, and installation of structural components.

Saudi Aramco’s ambitious stadium project in Al Khobar is progressing at pace, with more than 12,000 workers now active on-site as the energy major accelerates work toward its 2026 completion target.

Once delivered, the 47,000-seat venue will become the primary home of the Aramco-owned Al-Qadsiah Club. The stadium will be a cornerstone for the 2027 AFC Asian Cup as well as a host stadium for the 2034 FIFA World Cup.

According to its designer Populous, the project will be fully compliant with FIFA’s stadium requirements.

|

|

The stadium’s architectural design draws heavily from the natural whirlpools of the Arabian Gulf, expressed through interwoven, semi-transparent “sails” that wrap around the structure. |

The stadium and surrounding masterplan will be built over an area of approximately 800,000 sq m, incorporating a comprehensive range of community amenities and facilities designed to provide an unparalleled sports and entertainment experience, including new sports facilities, retail areas, entertainment zones and public realm spaces. It will feature cutting-edge technology and an integrated cooling system.

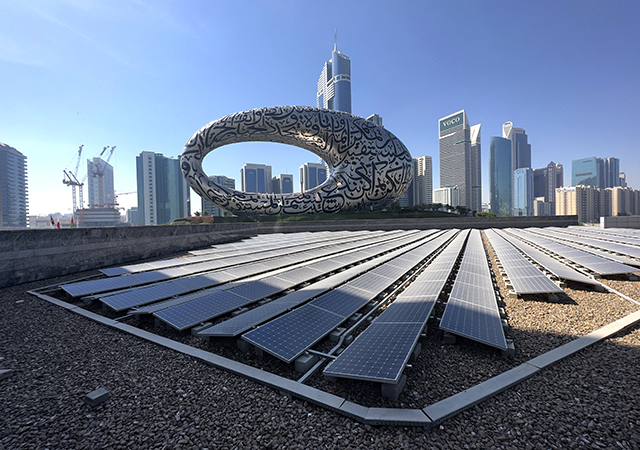

The stadium aims to achieve LEED certification for sustainability and will meet international inclusive design best practices to enable everyone to use and enjoy the venue on equal terms.

Aramco is developing the stadium in partnership with ROSHN Group, Saudi Arabia’s leading multi-asset class real estate developer and a Public Investment Fund (PIF) company, with major contractors such as BESIX and Al Bawani involved in delivering the structure and associated infrastructure.

STADIUM ROOTED IN GULF HERITAGE

The stadium’s distinctive architectural design draws heavily from the natural whirlpools of the Arabian Gulf, expressed through interwoven, semi-transparent “sails” that wrap around the structure. These forms rise dramatically upward, catching and reflecting sunlight to produce a glowing exterior during the day and a sculptural, illuminated presence at night. Aramco describes it as a modern artistic statement shaped by the rhythms and heritage of the region.

Drawing inspiration from Al Khobar’s location on the shores of the Arabian Gulf in the Eastern Province, Populous says it has created a dynamic and visually striking stadium exterior that expresses the graceful rotation of waves and the spiral motifs commonly found in nature. The overlapping translucent sails of the façade, delicately curved and proportioned, create a flowing sequence that allows natural light to penetrate the stadium’s interiors through strategically placed openings.

|

|

The project has surpassed 10 million safe working hours. |

Within the stadium, the spiral form of the building is echoed in the ramps and walkways that lead spectators to the seating bowl, which has been shaped elliptically to minimise the venue’s footprint and optimise natural ventilation. Developed by Populous’ specialist designers, the seating bowl will provide world-class viewing for football, with a compact configuration and uninterrupted views of the pitch from every seat. It will incorporate approximately 47,000 gross capacity, with a maximum capacity of 55,000 for concerts and other types of entertainment events.

Internally, the stadium integrates VIP areas, hospitality suites, and facilities designed for accessibility, ensuring full compliance with global standards. This inclusive approach aligns with the project’s ambition to serve not only as a sports venue, but also as a destination for tourism, entertainment, and community wellbeing.

The interior and hospitality spaces are the responsibility of specialist interior design practice Jump Studios, a Populous company, which has undertaken the spatial arrangement and concept design of the GA (general admission), hospitality, VIP and VVIP areas.

CONSTRUCTION PROGRESS

Work on the stadium has evolved into a round-the-clock effort, with teams engaged in shifts in welding, heavy machinery operations, and the installation of large structural components. The scale of activity reflects the urgency to meet tournament timelines and Aramco’s broader drive to deliver a world-class sports precinct for the Eastern Province.

According to Aramco, to date, the project has surpassed 10 million safe working hours, a milestone supported by rigorous on-site safety programmes and advanced digital oversight systems.

The stadium site is monitored continuously through a dedicated Safety Command and Control Centre (SCC). A wall of live surveillance screens displays camera feeds from across the site, enabling supervisors to track worker movement, environmental conditions, equipment operations, and emergency indicators 24/7. This centralised visibility is critical given the density of workforce and machinery on-site at peak activity periods.

Safety management is a central pillar of the construction strategy. Aramco’s Smart Safety Command Centre, which uses AI-driven tools to monitor site conditions in real time. Technologies include:

|

The stadium and surrounding masterplan is being built over an area of approximately 800,000 sq m. |

• 360-degree panoramic camera networks;

• Crane collision-prevention systems;

• Hook-mounted cameras supervising all lifting operations;

• A digital platform for inspections, audits, and safety observations;

• Drone surveillance for work performed at elevation, thus enhancing safety and supervision.

This integrated ecosystem allows supervisors to identify hazards immediately, improve coordination between teams, and maintain strict compliance with Aramco’s internal safety benchmarks.

On the ground, Aramco safety officers and heavy-equipment specialists are stationed at critical points across the site, overseeing machinery set-up, equipment movement, and major lifting tasks. Routine contractor meetings ensure alignment on key safety and worker health and welfare protocols, Aramco states.

WORKER WELFARE

Comprehensive training and welfare measures have been implemented to ensure the safety and well-being of workers at the Aramco Stadium project. Regular training sessions include orientation programmes for new workers, daily safety briefings, and group discussions emphasising safe and responsible work practices.

Given Al Khobar’s harsh summer climatic conditions, heat-stress management is a high-priority operational component. To protect workers from the extreme heat, specific initiatives have been introduced, such as training for both workers and supervisors on heat stress awareness and response. They are educated to identify symptoms of heat exhaustion, take preventive steps, and rest or seek shelter when necessary. Advanced heat sensors with alarm systems have been installed across the site to signal when temperatures reach hazardous levels, and work is suspended during peak heat hours in compliance with regulatory guidelines. In addition, worker welfare is prioritised through the provision of easily accessible drinking water, fully air-conditioned rest areas for meals and breaks, and high-standard catering services that deliver hot, nutritious, and hygienic food to all personnel, Aramco adds.

DESIGNED FOR GLOBAL STANDARDS

The Aramco Stadium is engineered as a multi-purpose venue, suitable for regional and international events. Integrated cooling systems will ensure spectator comfort during summer tournaments, while the design incorporates sustainability considerations across materials, mechanical systems, and operational planning.

The project also reflects Aramco’s continuing involvement in major sports infrastructure development. Its earlier landmark, the King Abdullah Sports City in Jeddah – home to the 60,000-seat Al Jawahara Stadium (Jewel Stadium) – opened in 2014 and set a precedent for large-scale, fast-tracked stadium delivery in the kingdom.

With construction advancing at full speed, the Aramco Stadium is set to become one of the kingdom’s most architecturally expressive and technologically advanced sports venues. Its combination of cultural inspiration, engineering ambition, and safety-first construction management places it among the standout regional megaprojects approaching delivery ahead of Saudi Arabia’s high-profile 2027 football commitments.

.jpg)

.jpg)

.jpg)

.jpg)