TarCoat being used to protect sewage tanks and manholes.

TarCoat being used to protect sewage tanks and manholes.

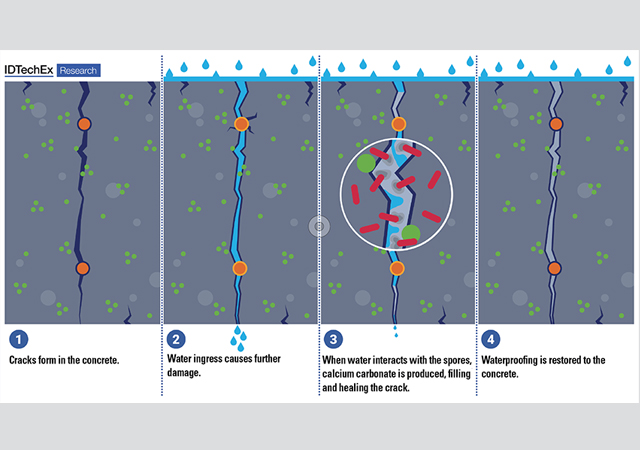

SAudi-based Construction Material Chemical Industries (CMCI), a leader in the construction chemicals market, has introduced an advanced waterproofing coating that is now being used by major clients in Saudi Arabia such as Saudi Electricity Company (SEC), Aramco and other major prestigious clients, says Bassam Bastaty, business development manager of CMCI.

Marketed under the trade name of Cemtec AL PU, it is an aliphatic polyurethane coating that is used for waterproofing areas exposed to direct sunlight.

The major advantage of this one-component, liquid-applied, moisture-cured, polyurethane coating is that it remains stable even under exposure to harmful ultraviolet (UV) rays that causes degradation of most coatings,” he points out.

Bastaty continues: “Over our past 20 years in the building industry, we have witnessed many failures of coatings that are not stable under long-term exposure to UV light. We, therefore, exerted tremendous efforts to search for a product that would withstand these damaging rays.

Other advantages of Cemtec AL PU coating are that it is extremely abrasion-resistant compared to other coatings and exhibits a non-yellowing characteristic which is ideal for exterior applications, he adds.

The product can be applied directly to a concrete or metal surface as well as to masonry and wooden surfaces. The application of the product is rather simple – by roller or brush – but for larger areas and to achieve the best results, CMCI recommends application by airless spray, he says.

“Many clients have expressed satisfaction with the new product, which is now being used as a waterproofing coating to protect the roofs of Aramco-built government schools. In addition, the product is now being used extensively by SEC to protect all of the foundations of the transmission towers.

CMCI – part of the Khalifa Al Gosaibi Group – holds a number of international licensee agreements.

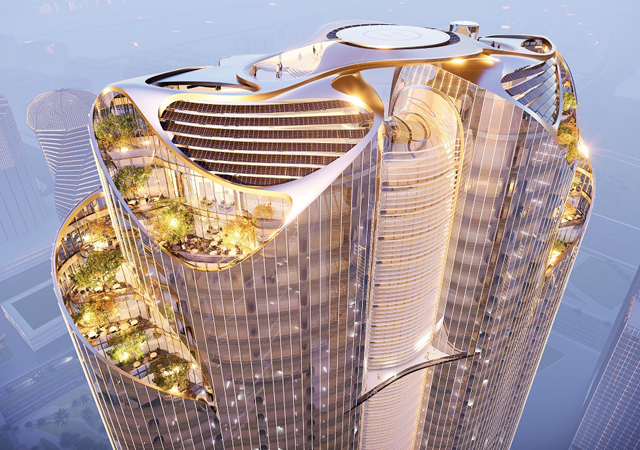

Another product that it has introduced successfully is TarCoat, a coal-tar epoxy protective coating. This solvent-free, two-component, high-build amine-cured coal tar epoxy coating, which has excellent adhesion to concrete and steel surfaces, was primarily designed to protect these surfaces against corrosion in aggressive environments.

“It is also highly recommended for steel tanks and pipe linings as well as for sewage tanks,” says Bastaty. “Most of the engineering firms are now recommending the use of coal tar epoxy to waterproof foundations and protect against chlorides, sulphates and sewage.

“The advantages of using coal tar epoxy are that it affords long-term protection against corrosion – which is an important factor in the Gulf – and its high resistance for chemical and abrasion.”

TarCoat is a high-build coating that is easy to apply by brush or spray and it requires no priming in most situations, he adds.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)