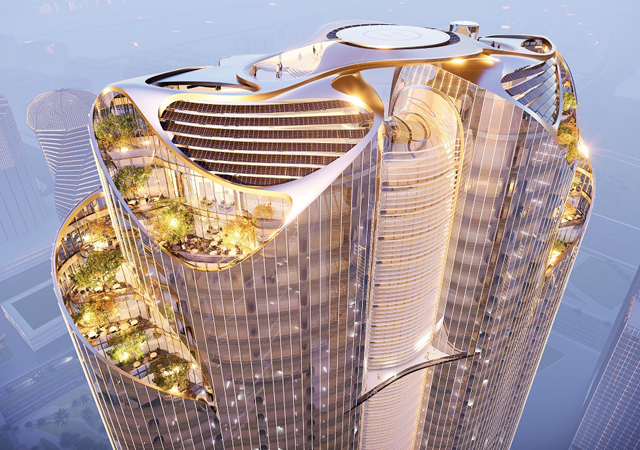

Sarnafil membranes have been installed on several sports complexes in Saudi Arabia.

Sarnafil membranes have been installed on several sports complexes in Saudi Arabia.

Switzerland-based Sarnafil says its waterproofing systems are suitable for all climatic conditions.

The company – whose success story began in 1964 when a new type of roofing material was required for an architecturally unique building that was to accommodate the Swiss Expo Centre in Lausanne – is now a leader in thermoplastic waterproofing membranes.

Over the years, Sarnafil has continued to be at the forefront worldwide in the development of poylmeric membranes for civil engineering applications such as basement waterproofing, for roofing and also for potable water applications.

Years of experience all over the world on art galleries, museums and computer clean-rooms alike has placed Sarnafil at the top of the list of suppliers who offer the most comprehensive and proven systems available worldwide, says a spokesman for the company.

Sarnafil membranes have proven themselves in a diverse range of applications, even in the harsh climatic conditions prevalent in the region, says the spokesman. The company boasts a string of projects that have stood the test of time in the Middle East.

Sarnafil offers membrane systems that are designed for basement waterproofing applications.

“Below-grade water infiltration can cause damage and limit the use of valuable space. Protecting the building’s foundation from ground water and run-off is a sound investment,” the spokesman comments.

Roofing

For roofing projects, Sarnafil offers PVC membranes in a full range of colours and a product called Decor Profile, which simulates a standing seam roof.

Sarnafil was the pioneer in FPO (flexible polyolefines) membranes, which were developed by the company in response to increased ecological sensitivity in the 1980s.

The light-coloured surface of Sarnafil membranes offers superior weatherability performance in the most severe climatic conditions, he says. These membranes are offered in a range of colours and with all the required accessories.

“All Sarnafil membranes are uniquely capable of being applied in the most demanding architectural applications,” says the spokesman. “Some of the world’s most striking buildings have been roofed with Sarnafil.

Sarnafil roofs are in place and performing in vastly different areas of the globe – from the Antarctic and Siberia to the tropics of Africa and the extreme heat and ultraviolet exposure in the Middle East.

“Sarnafil roofs have been installed in Saudi Arabia as far back as 1969 on a power plant project in Riyadh. Other projects that have been in place for 20 years or more include a military hospital which involved a total roof area of 10,000 sq m, installed in 1978. In the same year, 80,000 sq m of roofing was installed at the hospitals for the Ministry of Health,” the spokesman says.

Other roofing projects were carried out at an RSAF (Royal Saudi Air Force) housing development in Riyadh (200,000 sq m), King Khalid Military City (80,000 sq m) and Qatif Sports Complex (6,500 sq m).

Potable water

Sarnafil also plays a role in preserving the supply and quality of drinking water. It keeps tanks and reservoirs watertight, with specially-developed membranes and systems specifically for potable water applications such as tanks. Sarnafil has proven itself as the appropriate material for such applications.

The company has already installed more than 32,000 sq m of its membranes for two 10 million gallon tanks in the Al Ajban area of Abu Dhabi, UAE.

In Saudi Arabia, it has carried out projects at the Makkah Hotel, an ice storage tank for Qassim power plant and the Prince Sultan Military City.

“Sarnafil FPO membranes have been installed over a suitable substrate and protective layer and – by virtue of its heat-welded seams that require no solvents or harmful chemicals – a monolithic, completely watertight membrane system is created that will remain in place and perform for years to come,” he explains.

Support

“One of the biggest advantages of choosing and working together with Sarnafil," says the spokesman,” is certainly the quality of the Swiss products. However, products are only as good as they are designed and installed.”

Realising that design and installation play a critical role in the successful execution of project, Sarnafil offers a full ranges of technical services, and support from design review, wind-uplift and other performance calculations as well as on-site technical supervision. Most of all, Sarnafil may only be installed by an applicator who has been trained and educated in the proper techniques, he adds.

To demonstrate that Sarnafil is prepared to stand by its products, it offers a 10-year material guarantee – available directly from the company.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)