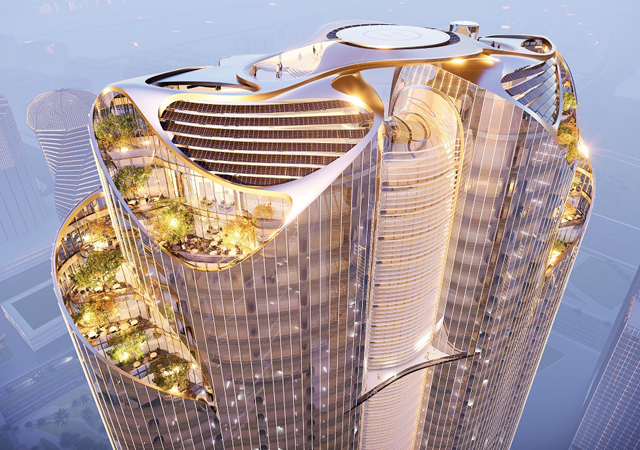

The K-Master machine shown here being trialled in Dubai.

The K-Master machine shown here being trialled in Dubai.

International flooring specialist Flowcrete is currently involved in two of Dubai’s largest and most high-profile projects: the retail development at the mammoth Dubai Festival City project and the extension at Dubai International Airport, where it is supplying hundreds of thousands of square metres of specialist flooring.

For the Dubai International Airport expansion project, Flowcrete has secured a contract at the new Terminal 3 (Package AX059) involving a total of 365,000 sq m of its car-park decking system, Deckshield. The largest airport development in the world, the project involves construction of the new Terminal 3, two new concourses, a cargo mega terminal and expansion of Terminal 2.

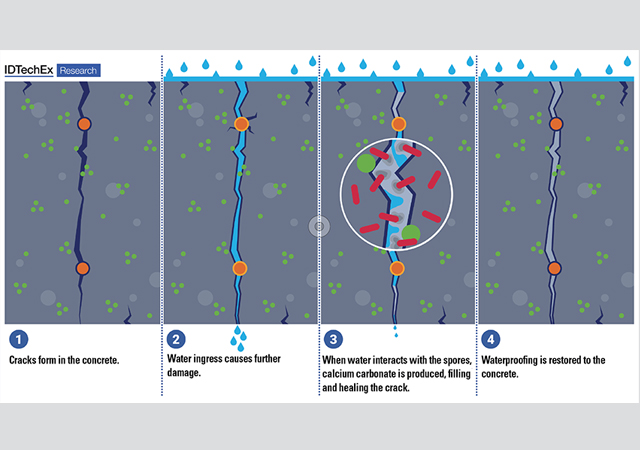

According to Douglas Currie, regional specifications manager for Flowcrete International, one of the major problems facing building owners and facility operators is damage to the structure of the building caused by water and salt ingress, especially in the hot, humid and saline conditions in the Arabian Gulf.

“Car-parks are particularly prone to this kind of damage, and in multi-storey structures – where the decks are subject to movement – a rigid flooring finish such as concrete or epoxy will crack,” he says. “As well as looking unattractive, cracks in concrete floor surfaces add further risks to the equation. The reinforcing steel is exposed to corrosion as a result of the water and salt ingress. With a waterproof, crack-bridging, flexible polyurethane system like Deckshield, these problems are eradicated.”

Over 3 million sq m of Deckshield have been installed worldwide, including at Kuala Lumpur International Airport, one of the largest multi-storey car-parks in the world where 240,000 sq m were installed. The system was also used for the car-park facilities at Hong Kong’s Chep Lap Kok Airport.

“This international track record, along with 500,000 sq m installed in the UAE alone, was a key factor in securing the Dubai Airport contract,” says Flowcrete Middle East regional manager Dev Sirwani. “There are a number of reference sites in Dubai – the largest to date being the car-park at the new BurJuman Centre development. This enabled us to demonstrate first-hand the results achievable with Deckshield.”

Materials are due for delivery in Dubai from this month onwards and the phased installation is scheduled for completion by the fourth quarter of next year. The work will be carried out by Flowcrete’s approved applicator Pegasus Contracting.

Managing director of Pegasus Ian Graham comments: “We have handled all of Flowcrete’s Deckshield contracts to date, a track record of some half million sq m in the UAE alone. We are delighted to be adding this huge and prestigious project to our portfolio.”

A contract has also been secured for 30,000 sq m of Deckshield UV for installation at the multi-storey car-park used by airline employees at Gate 13.

“The structure includes an exposed rooftop car-park deck. The high UV (ultraviolet rays)-resistant properties of the Flowcrete system will protect the surface and ensure its integrity for much longer than a conventional surface such as concrete,” adds Sirwani.

Screeding

At the massive Dubai Festival City development, a total of 350,000 sq m of screed is being installed in the retail areas. Flowcrete’s semi-dry cementitious screed system known as K-Screed has been selected and licensed applicator Advance Screeding Limited has begun work on the first phase of the project – an area of almost 100,000 sq m.

“The Festival City contract follows many other K-Screed installations in the Gulf region, however, this is first time that the revolutionary K-Master machine is being used,” says Vic Cottom, managing director of Advance Screeding. “This highly innovative piece of equipment is set to transform screed installation in the industry. Automatic operation enables a consistent and high-quality result to be achieved, with a steady production rate of up to 60 sq m per hour.

“The installation rates achievable with K-Master are dramatically higher than with manual installation. The integral screed peel-off calender also means that large areas of screed can be laid easily without the back-breaking effort involved with manual installation. The resulting screed is level, flat and perfectly compacted. K-Master is a joy to work with.

“Weighing in at just 50 kg and offering a variable working width from 2 m up to 3.6 m, K-Master is easy to operate and manoeuvre – another benefit for applicators,” Cottom adds.

Unlike conventional sand and cement substrates, K-Screed offers a high-compressive strength and low water-cement ratio, which minimises shrinkage and cracking and with much faster drying times. It provides a smooth, durable surface as a base for the final selected floor finish, such as epoxy resin, fitted carpet, wood, tiles or vinyl, says Sirwani.

Royal Flight

After many rounds of technical discussions with the client and the consultants, Flowcrete has added another highly prestigious project to its order book. A total of 55,000 sq m of Flowcrete’s specialist systems are being installed in the eight private aircraft hangars and workshops of the Dubai Royal Family.

“Flowcrete’s Flowcoat SK (UV Stable) was chosen against stiff local and international competition, being the only system able to meet the very high specifications for chemical and UV resistance,” says Currie.

The project is currently nearing completion.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)