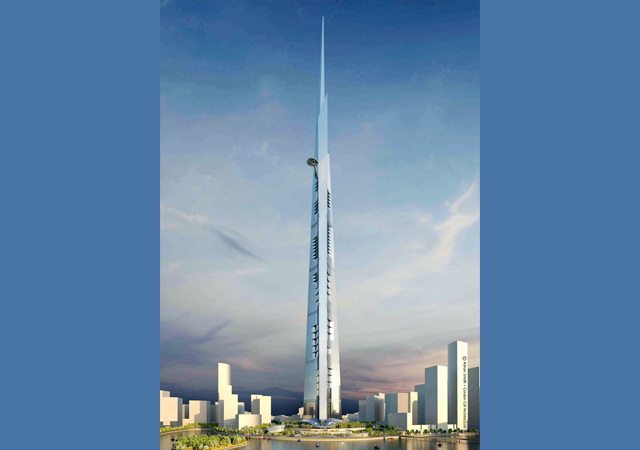

The twin towers in the Diplomatic Area ... featuring BPC’s precast fin panels.

The twin towers in the Diplomatic Area ... featuring BPC’s precast fin panels.

BAHRAIN Precast Concrete Company (BPC) marked a major milestone in its history last year: the precast manufacturer celebrated 30 years of leadership in Bahrain’s precast concrete industry.

It was also a year that saw BPC perform well, despite it being a tough year, and complete a string of prestigious projects.

“The market was highly volatile in 2008 with a scarcity of raw materials such as steel, cement, and aggregates and skyrocketing prices. This, coupled with the global financial crisis and cash crunch, has had a major impact on Bahrain’s construction industry in general and the precast industry in particular,” says Goran Hogberg, general manager of Bahrain Precast Concrete Company. “Many projects have been delayed and new projects held up.”

Hogberg, however, is satisfied with the company’s performance in 2008 and looks to a promising 2009 despite the uncertainties looming over the construction industry.

Hogberg is particularly pleased with the company’s performance in the hollowcore products sector. “Hollowcore sales during 2008 have been very good though not at the same level as 2007, due to shortage of cement and other construction materials. Our 500-mm slabs are finding good applications in car-parks and shopping complexes as they come in longer spans and allow a lot of column-free area for the movement of vehicles and people.

“We expect 2009 to be very good year for hollowcore slabs as a lot of major projects are in line for execution,” he adds.

“The raw materials situation has eased and we expect the financial scenario and cash availability to improve in the near future and new projects to be launched. BPC’s order book for 2009 is quite full and more orders will follow as the situation improves,” he comments.

Some of the major projects that BPC is involved with include the Zallaq Resort which entails the design, supply, delivery and erection of 7,600 sq m of 230-mm-thick external cladding panels in beige coloured concrete with Ras Al Khaimah aggregates. The surface finish will be fair-faced using the acid-washing technique.

BPC is currently supplying its precast structures system (PSS) to two major tower projects in the Seef District. These include a 35-storey building, for which BPC is engaged in the design, supply, delivery and erection of 400-mm-thick shear walls, precast (PC) columns in various sizes, PC circular columns, precast beams in various sections, staircases, 200-mm-thick solid slabs and 150-mm, 265-mm and 500-mm-thick hollowcore slabs. The second project is a 24-storey twin-tower, which involves design, production, delivery and erection of 350-mm, 300-mm, 250-mm and 200-mm-thick shear walls, 120-mm-thick parapet wall panels, PC columns; PC normal and pre-stressed beams and 150-mm, 200-mm and 400-mm-thick hollowcore slabs.

BPC is also carrying out the extension of Sacred Heart School in Isa Town. The contract calls for the design, supply, delivery and erection of 200-mm and 250-mm-thick load-bearing cladding panels, parapet panels, non-load-bearing panels, beams, columns, staircases and hollowcore slabs.

Meanwhile, BPC ongoing projects portfolio also includes two multi-storey car-parks. These are a 13-storey building (eight storey car-park and five storeys for offices) facility at Gulf Hotel, which entails the design, supply, delivery and erection of 200-mm-thick protection panels; precast arches; 200-mm, 265-mm, 320-mm, 400-mm and 500-mm-thick hollowcore slabs. BPC has recently commenced erection of the hollowcore slabs at the project site. The second car-park is located at Arad and calls for the design, supply, delivery and erection of 250-mm-thick shear walls, 600 by 600 mm columns, beams, parapets, staircases and 200-mm and 500-mm-thick hollowcore slabs.

Over the past year, the precast concrete specialist has completed a number of prestigious projects in Bahrain, which has involved design, production, delivery and erection of a range of precast elements. These included:

• The Royal College of Surgeons in Ireland Medical University of Bahrain (RCSI-MUB) in Busaiteen. BPC’s scope of works covered external-pigmented insulated panels, beams, column claddings, externally insulated load-bearing panels, external elements and hollowcore slabs (150 mm, 200 mm, 265 mm and 400 mm);

• Aviation Tower (airport control tower) (200-mm-thick internal load-bearing panels, 400/150-mm tapered panels, 200-mm-thick insulated load-bearing white precast peripheral walls, 150-mm and 200-mm-thick hollowcore slabs and construction of in-situ foundation/substructure);

• Ali Kanoo Health Centre in Nuwaidirat (250-mm-thick externally-insulated load-bearing panels, 150-mm-thick external panels, 120-mm-thick side parapet panels, straight and circular columns, beams, staircases, boundary wall and 150-mm-thick hollowcore slabs);

• A 13-storey precast building in Hoora (300-mm, 250-mm and 200-mm thick externally-insulated load-bearing panels, 300-mm, 250-mm and 200-mm-thick shear walls, 300 by 400 mm columns, beams, staircases, perimeter walls for a swimming pool and 150-mm and 200-mm-thick hollowcore slabs);

• The 18-storey Park Tower in the Diplomatic Area (250-mm and 300-mm-thick shear walls, columns, PC pre-stressed beams, PC beams, staircases including landings and flights and 150-mm, 200-mm and 240-mm-thick hollowcore slabs);

• Al Jawhara Building in Salmaniya (120-mm-thick pigmented precast cladding panels);

• A precast building system at the Police Fort (precast foundations, columns, normal beams, pre-stressed inverted T beams, 250-mm-thick insulated load-bearing panels, internal load-bearing panels; PC staircases and 150-mm, 200-mm and 320-mm hollowcore slabs);

• 16-storey twin towers in the Diplomatic Area (PC fin panels with fair-faced finishes and 150-mm, 200-mm and 265-mm-thick hollowcore slabs); and

• Toyota car-park in Tubli (250-mm-thick shear walls, 120-mm-thick parapet walls, columns, staircases, 250-mm-thick external wall cladding at ramps and 320-mm hollowcore slabs).

Meanwhile, as part of its 30th anniversary celebrations earlier last year, the company hosted a customer’s party in April at the La Fontaine Center of Contemporary Arts and introduced two new products: BPC flat slabs and precast foundations.

BPC flat slabs are also another first in the GCC providing a cost-effective, safe and reliable solution for roofs, explains Hogberg. BPC estimates that using this product its customers will be able to save up to 30 per cent in time and up to 20 per cent in cost compared to conventional construction methods. The product is suitable for applications up to a maximum of 6 m by 6 m modules and residential loadings. For longer spans and higher loadings, the company recommends its wide range of hollowcore slabs. The precast foundations are designed to meet today’s demand for fast-track construction by reducing the project time required.

BPC also conducted a seminar at the University of Bahrain to increase awareness of the precast technology among civil and architectural engineering students. To mark the occasion, BPC has also published a book on precast technology, which is distributed free of cost to its clients.

(5).jpg)

.jpg)