Ikea hypermarket in Riyadh ... a Zamil Steel building.

Ikea hypermarket in Riyadh ... a Zamil Steel building.

HAVING seen promising signs of an upturn in the market, the Pre-Engineered Building (PEB) division of Zamil Steel is hopeful of making further gains in its global export arena in the year ahead.

The Dammam-based company, one of the largest manufacturers of PEBs in the world, has witnessed a 14 per cent increase in its business levels over the past year and believes prospects are good for this year as well, given that the demand for steel buildings is on the rise.

Zamil Steel manufactures more than 500,000 tonnes of steel products annually, sold in more than 90 countries through an international network of dedicated sales and representative offices, certified builders, agents and distributors. It produces low-rise and high-rise steel buildings and structures for a diverse range of industrial, commercial, agricultural, aviation, entertainment and military applications as well as for supporting infrastructure and development projects.

The PEB division, which on average handles more than 1,000 new projects per year, is aiming at increasing its share in the existing markets, in addition to exploring new markets of potential business worldwide, in line with the global market recovery.

“We see bright prospects for Zamil Steel over the coming year,” says George Kobrossy, Zamil Steel’s corporate marketing and business development director. “We have been noticing signs of a healthy market recovery (following the global financial crisis) in several countries and in various segments of the industrial, commercial and institutional construction sectors. Given our large network of sales offices, builders and business alliances, well distributed in strategic locations around the world, Zamil Steel is well placed to maintain its business levels and achieve its targets.”

The Saudi economy, in particular, has been buoyant, which has reflected positively in industries, like steel buildings manufacturing, according to him.

|

|

Spare parts showroom for Al Masaood in Abu Dhabi, UAE. |

“There are significant opportunities for growth in the region, as governments plan to invest in huge construction projects.

This is also the case with the private sector where we also anticipate significant growth in investment,” he adds.

The financial downturn, Kobrossy says, has affected various sectors of business in most countries in the world and Zamil Steel, being part of the international community, has had to tackle any repercussions on its business. “However, as an industry leader, we maintained our market share by continuously excelling in engineering, manufacturing, sales and project management and offering clients a diverse range of products, thus offering total building solution packages. We are always appraising opportunities for entering into new markets through a direct presence, or through certified builders and agents.”

Being one of the most trusted brands among steel building customers, he says, Zamil Steel has been able to improve its market share, and to reposition the company in line with global challenges.

Zamil Steel’s success in the market can also be attributed to its proactive approach which has seen some major developments within the company over the past year. It has launched new panel types such as the standing-seam roof system (Max Seam), a fastener-free roof system and introduced automated spray painting into its production process, which is expected to decrease production cost while increasing overall productivity. Furthermore, it has created a new division – the Zamil Steel Prefabricated Division or “HouseZ” brand – to introduce pre-fabricated housing. Zamil Steel will also be actively marketing open web joists as well as metal floor decking (standard and composite).

|

|

Zamil Steel’s major international orders included 3,308 tonnes for the expansion of the Honda factory in Vietnam |

To enhance its support and services to customers, the company has introduced a value-engineering team and developed software for its customer service department. It has also turned to RFID (radio-frequency identification) technology to support supply chain management.

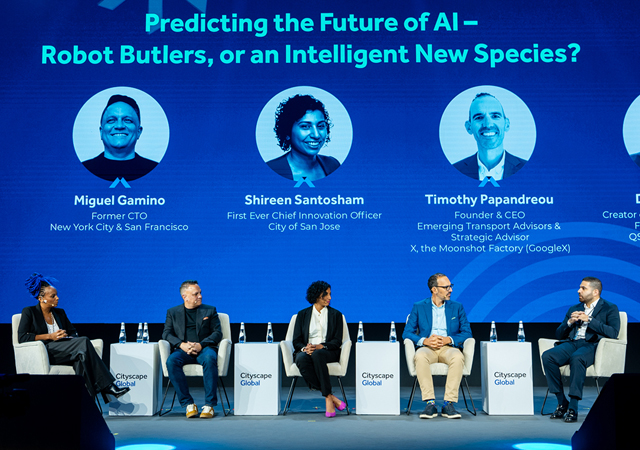

To increase its market penetration, Zamil Steel has been a regular participant in local and international exhibitions and forums with the aim of achieving better exposure and reaching out to new markets.

The company has also excelled because it has abided by the principles of pre-engineered steel buildings, which were developed to provide the building industry with the most practical and optimised building solutions. “A steel buildings manufacturer must demonstrate certain competencies in order to best serve the interest of investors and meet the full satisfaction of customers. These include design capabilities for structural integrity, optimised solutions for cost saving, fabrication capacity for faster delivery, erection experience for final quality, and after-sales service for peace of mind.

“It is well known in the construction industry in the GCC and elsewhere that Zamil Steel has it all,” Kobrossy asserts.

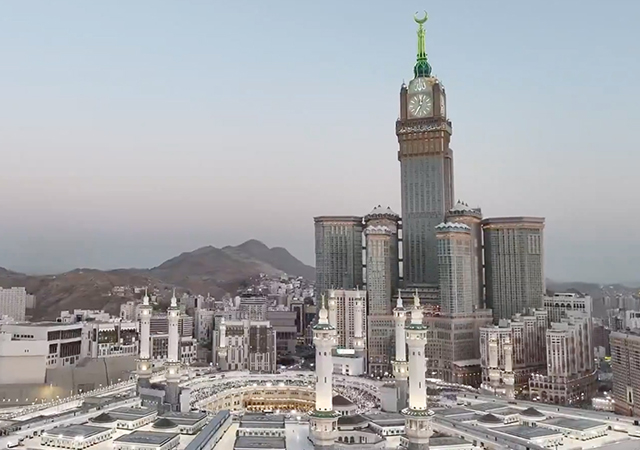

The firm’s steel buildings have been utilised in various applications in numerous industries. Recent examples in Saudi Arabia, that showcase this diversity of applications include a paper factory for Arab Paper Manufacturing and the roof for a multi-purpose hall for Shehab Readymix in Dammam; a hypermarket for Abyat in Dhahran; a warehouse for Mosa Sultan and several hypermarkets for Panda in Riyadh, a shopping mall for Mall of Arabia in Jeddah, and an aircraft hangar for Saudi Oger in the kingdom (3,200 tonnes).

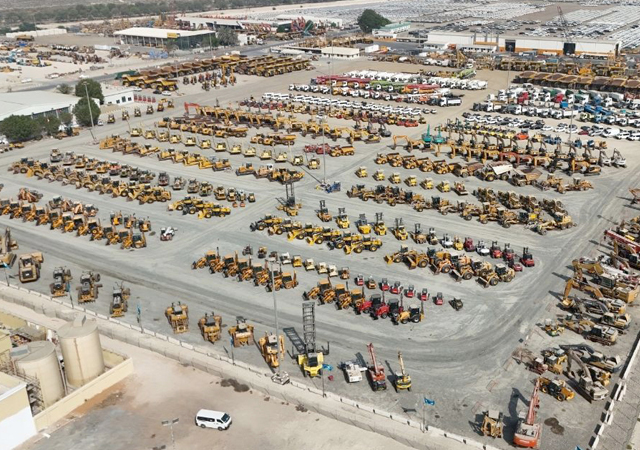

Zamil Steel buildings also accommodate a spare parts showroom for Al Masaood in Abu Dhabi, UAE, and distribution centres for Al Sayer Centre for Spare Parts in Shuwaikh, Kuwait.

|

|

2,700 tonnes for the Changi Airshow Exhibition Centre. |

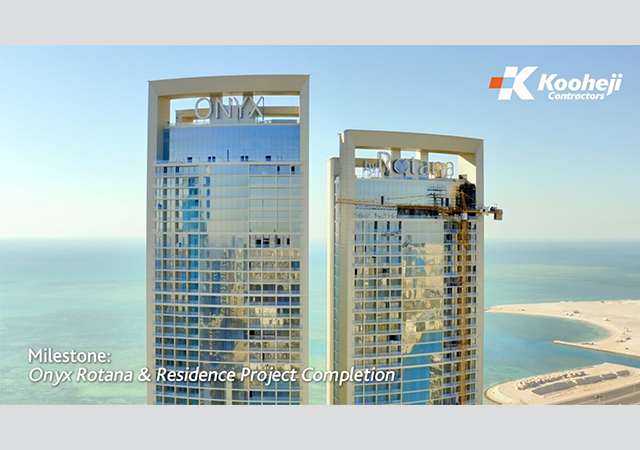

Other major international projects include the Honda Vietnam factory extension for Hazama Corporation, which involved more than 3,300 tonnes of steel, and a recreation facility for Hanoi Golf Club, both in Vietnam; the Changi Airshow Exhibition Centre for Eng Lim Construction in Singapore (around 2,700 tonnes of steel); ; a hangar for the office of the Chief of Defense Industries in Myanmar; and a school for STA Educational Group in Bangladesh.

Dammam-based Zamil Steel, founded in 1977, is widely recognised as the Middle East’s premier supplier of pre-engineered steel buildings, structural steel products, process equipment, transmission and telecommunications towers, pre-fabricated houses, open web steel joists, sandwich panels and a variety of steel building components.

The company has six business divisions namely, Pre-Engineered Building Division (PEB), Structural Steel Division (SSD), Towers and Galvanising (T&G), Process Equipment Division (PED), Building Components (BCOMS), and Pre-Fabricated Houses (HouseZ).

Zamil Steel serves the global steel industry through a network of 62 area offices in 37 countries, and a wide network of certified builders. These offices are fully staffed and equipped to provide clients with comprehensive quotations and proposal drawings, respond to various enquiries, support for ongoing projects and extensive after-sales services.

A significant number of people are employed in its offices worldwide, with staff distributed over several factories in Dammam (Saudi Arabia), Egypt, Vietnam, UAE and India as well as deployed in representative offices located in other countries. Amongst these employees are more than 600 design engineers in its engineering departments in Saudi Arabia, Egypt, Vietnam and India.

.jpg)