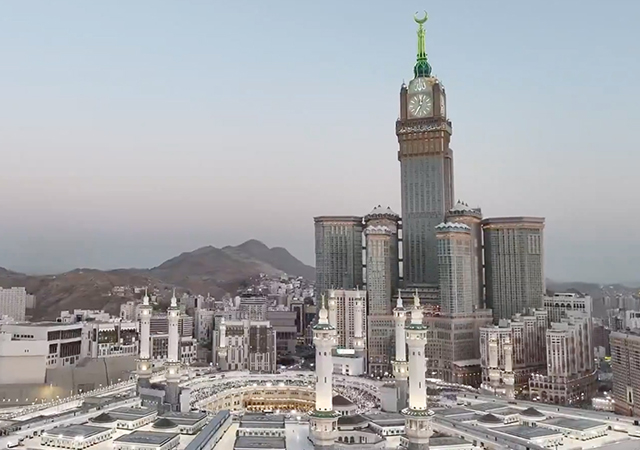

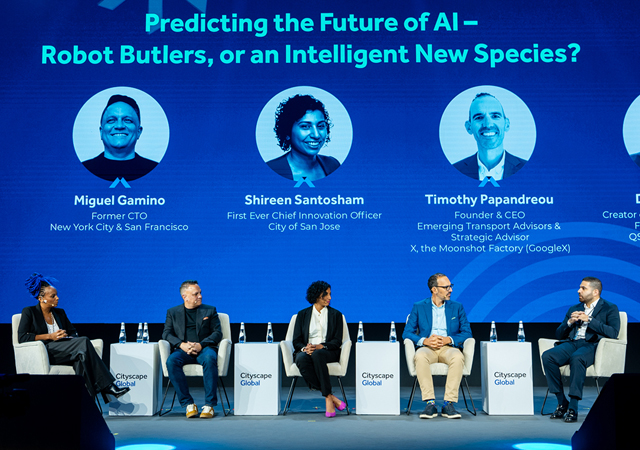

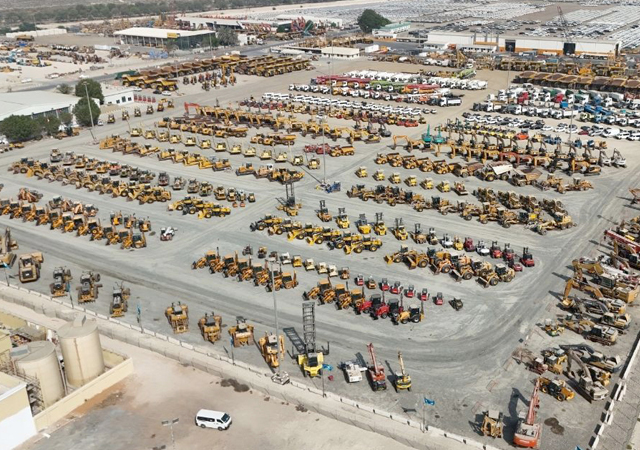

A project being built using Sibco’s insulating blocks

A project being built using Sibco’s insulating blocks

WITH the increasing awareness of the need to use energy-efficient products, Saudi Insulated Blocks Company (Sibco) reports a keen interest in its insulating concrete blocks that offer a host of advantages over their conventional concrete counterparts.

These insulating blocks made of autoclaved aerated concrete (AAC) – a Swedish invention consisting of cement, sand, water, and gypsum – boast a number of benefits including thermal and acoustic insulation, structural strength and fire and earthquake resistance.

Since its establishment in 2007, Sibco has grown rapidly to become one of the leading producers of these cellular concrete products blocks in the kingdom and the Gulf.

Sibco specialises in the manufacturing of insulating white blocks to serve Saudi Arabia’s growing construction industry. It uses the latest production equipment and machinery to manufacture products to international standards.

The company has established two factories, one each in Riyadh and Jeddah, for the production of this type of concrete, which combines the strength of traditional concrete with the benefits offered by cellular concrete, making it the preferred choice for buildings around the world, says Tarek Olama, a spokesman for the company.

Cites some of the key properties enjoyed by these blocks, he says: “The thermal conductivity of insulated blocks is at 0.12 to 0.14 W per m deg K, which means that these lightweight blocks provide four times better insulation than red clay blocks. It also insulates 10 times better than traditional concrete which, in turn, helps reduce energy consumption.

These properties ensure a comfortable indoor atmosphere while protecting furniture from extremes of temperature.

Studies carried out by the Research Institute of King Fahad University of Petroleum and Minerals have proven that by using insulated blocks, some 40 to 60 per cent of the electricity consumption can be reduced, which brings down costs for the citizen and the country.”

These blocks can be used as structural elements to construct building walls, wall panels and reinforced ceilings. They are resistant to various weather conditions and enjoy dimensional stability. Thousands of public buildings such as colleges, schools, hospitals, hotels, office buildings have been built using insulated blocks, with a compressive strength of 3 to 5 N per sq mm.”

The acoustic properties of Sibco’s blocks are on par with international standards for use in buildings and a wall thickness of 20 cm achieves a sound reduction of up to 42 dB.

|

|

Olama ... preferred choice. |

Composed of inorganic material, the blocks are non-combustible and do not release any harmful gases when exposed to fire. “The tests that have been conducted on these blocks indicated that at thickness of 15 cm, they can resist fire for seven hours according to ASTM – a key factor for public facilities such as schools, hospitals and hotels,” Olama says.

Comparing these cellular blocks with conventional concrete, he says that conventional concrete is heavy and requires the construction of a thicker foundation and columns to support the weight, which means higher costs, extra labour and more time. Insulated blocks, however, have a density of 500 kg per cu m – compared to 2,300 kg per cu m for conventional concrete – which dramatically reduces the amount of steel and materials used in structures, he says.

In addition, these blocks also provide other cost savings in terms of transport, and the number of sand heavy installation equipment used.

Another benefit afforded by these blocks is earthquake resistance. “Being lightweight, they are less prone to seismic stress and over the last 70 years, this fact has been proven in various parts of the world,” he concludes.

.jpg)