The Research and Development Centre ... now complete.

The Research and Development Centre ... now complete.

Jeddah-based Almabani General Contractors currently has projects worth around $500 million under execution throughout the Kingdom, right from Al Khobar on the east coast to Jeddah in the west.

Among the most prestigious projects it is currently involved is the Sultan Bin Abdulaziz City for Humanitarian Services, a medical city project in Riyadh (see separate report) and the Emergency Care Center and Long Term Care Center, both in Riyadh.

On a more specialised level, the company is carrying out the expansion of the existing seawater cooling system as well as upgrading the reverse osmosis (RO) units and support facilities in the Industrial City of Jubail for the Royal Commission for Jubail & Yanbu - Directorate General for Jubail Projects.

In Al Khobar, it is building a science and technology centre which is believed to be the only one of its kind in the Kingdom (see separate report).

Laboratory R&D Centre

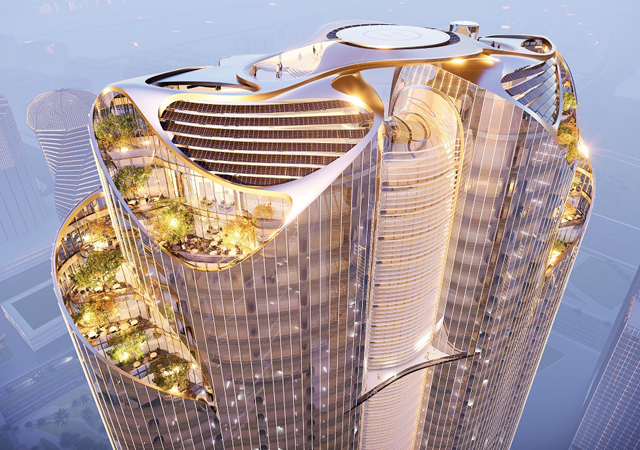

Among the more challenging projects just completed this year is Phase I of the Laboratory Research and Development (R&D) Centre in Dhahran for Saudi Aramco, over a total site area of 13,700 sq m.

The SR154.5 million ($41.1 million) project, completed in March, comprises an R&D centre housing 80 offices, a main conference facility, six additional meeting rooms and a basement that accommodates a control centre manned round-the-clock, as well as utilities and support facilities.

Almabani carried out the lumpsum procure and build (LSPB) contract in consortium with Jaffar M Al Hamood. It covered the material procurement and construction of a three-storey general laboratory building with a partial basement and two-storey hi-bay buildings including support facilities such as shaded storage areas and utility yard, chiller plant, electrical switching stations, 174 parking spaces, covered walkways from the parking areas, access road and landscaping. The actual built-up area is 4,945 sq m.

The contract also included laboratory casework and furniture and building maintenance equipment, such as window washing equipment and cranes.

''Construction of Phase 1 began in December 1998 and was completed on schedule, within budget,'' says Ghassan El Khazin, area manager. ''The job was completed with a sterling safety record. The contractor completed 2.6 million man-hours without an industrial disabling injury from December 1998 to October 2000.''

''The highly exacting safety requirements of Saudi Aramco posed a great challenge to the consortium of Almabani and Jaffar Al Hamood.'' Khazin points out. ''The consortium's effort to respond to client's stringent requirements earned it the most coveted Contractor's Safety Competition Award in 1999 and First Place in Construction Contractor Excellence Program in 2000.''

Royal Commission projects

Almabani is currently working on two projects worth a total of SR350 million in the Industrial City of Jubail for the Royal Commission for Jubail and Yanbu - Directorate General for Jubail Projects.

It is implementing both the LSPB contracts in joint venture with Saudi Condreco Limited, with the consultant being Saudi Arabian Bechtel Company (Sabco).

Under a SR267 million deal, the joint venture is engaged in the procurement and construction of a seawater cooling pumphouse No. 2 in Jubail. Work started in January 1998 and was completed and initially accepted last September.

Disassembly, reassembly, inspection, testing and commissioning of the installed pumps including demobilisation are expected to be finished by May 2002.

''Saudi Basic Industries Corporation (Sabic) envisions the rapid growth of basic industries in the Kingdom,'' Khazin comments. ''And to sustain it, expansion of the required infrastructure of the industrial cities was essential. Almabani in association with Saudi Condreco is involved in the construction of one of the key projects of the Royal Commission - the expansion of the existing seawater cooling system.''

The project calls for the expansion of the existing seawater cooling system and covers a total area of 136,000 sq m with an actual built-up area of 46,500 sq m. Implementation of the expansion involves construction of:

''The major challenge in heavy industrial construction is its being 'heavy' itself,'' says Adel Monsef, project manager. ''Concrete pouring of huge structures requires proper coordination of manpower and equipment, properly installed and well-supported formwork, consistent mixtures and steady supply of concrete and additives, and continuous availability of manpower.

''Almabani and Saudi Condreco, in several instances, had a continuous concrete pouring activities of more than 1,000 cu m for more than 48 hours. The total volume of concrete poured in this project was 40,000 cu m.''

Almabani and Saudi Condreco are also engaged in upgrading the reverse osmosis (RO) units and support facilities in Jubail under a SR83.19 million contract. Work commenced last September and is expected to be finished in September 2003. It involves:

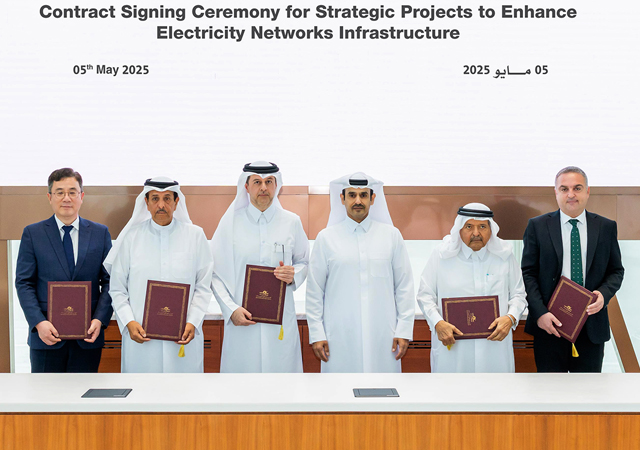

In Yanbu, Almabani is building an electrical substation and the associated cabling for the Royal Commission for Jubail and Yanbu - Directorate General for Yanbu Projects - under a remeasured contract worth SR53.68 million.

Work, being implemented in joint venture with Abdullah Al-Khodari and Sons, is slated for completion in October 2002.

The project includes engineering, procurement, and construction, installation, testing and commissioning of the required infrastructure including streetlighting and signalling systems to support development of residential and commercial areas in the Industrial City of Yanbu.

It covers 13.8 kV power distribution and streetlights for Haii Al-Jubail areas A and B; streetlighting for the extension of Shareh Al Malik Abdulaziz (TAMA) to Shareh Al-Yarmuk and a new 450 sq m substation 2L in Haii Al-Jubail, including 45 kV circuits rated 40 MVA from Substation 2B.

''Some delays in the design process affected the overall schedule of the project,'' Khazin admits. ''However, with the sheer determination of the management team to put the project back on schedule, the original target of five months to install 172 km of underground electrical cables was completed in only two months.''

The consultant on the substation project is Parsons Saudi Arabia.

ECC & LTCC buildings

Work is nearing completion on the Emergency Care Centre (ECC) and Long Term Care Centre (LTCC) at Khashm Al Aan, Riyadh, for the Saudi Arabian National Guard (Sang) under a LSPB contract worth SR40.44 million. The consultant on the project is Joint Engineering Team (JET).

The project consists of design and construction of a two-storey LTCC building and a single-storey ECC building with electrical substations, car-parking, sidewalks and landscaping over a 10,000 sq m site. Each building is furnished with medical and non-medical equipment and furniture, including special systems. The actual built-up area is 6,296 sq m with the LTCC covering 3,093 sq m and the ECC 3,203 sq m.

It includes conveying systems, adequate power supply from the substation/generator room, and the complex is provided with complete services and other special systems such as a pneumatic tube system and a medical gas system.

The concrete structures have external CMU fluted blocks.

Electrical works cover electrical substations, generators and transformers, medium and low cables, ATS and ring main units.

Gosi building

Almabani is close to completing work on its SR2.45 million re-measured contract for structural remedial works on the Gosi (General Organisation for Social Insurance) Commercial Building No. 1 in Dammam.

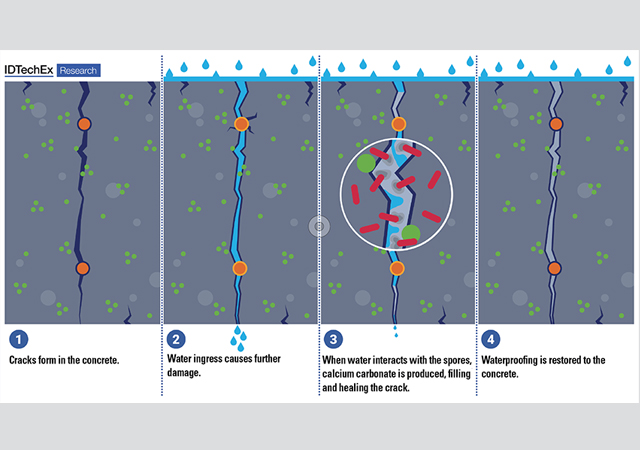

''The building was constructed in 1981 and has recently exhibited serious signs of deterioration. This prompted the client to implement remedial works to restore stability of the structures,'' Khazin explains.

Al Rabiah Cowi Consulting Engineers is the consultant on the project.

''The structure comprises a 12-storey construction and a basement that covers the entire area of the building. The ground, mezzanine, service and restaurant floors slabs are solid slab constructions with different thicknesses depending on the framing plan of each floor,'' explains Elie Chrabieh, specialities division general manager.

The particular scope of work covered in the rehabilitation of the structures comprises: Basement retaining walls and soffits, ground and restaurant floor slabs, sixth floor level, columns, core walls, cladding panels, expansion joints and roof waterproofing.

Conventional repair methods used were sandblasting, concrete re-skinning, steel reinforcement strengthening and application of protective coating to new concrete to prevent salt intrusion.

Work is being carried out without vacating the occupied units not included in the contract. Noise level and disturbance to tenants and traffic flow were limited to a minimum.

Completed projects

Almabani also completed work last month (April) on the rehabilitation of concrete structures at Saudi European Petrochemical Company's (Ibn Zahr) plant in Jubail.

Under a remeasured contract worth SR800,000, Almabani Specialities Division undertook the concrete rehabilitation works, comprising mainly the suspended slab of the seawater intake basins, anchor block for flare tower and miscellaneous vessels foundations.

''Some works has to be executed during the plant shutdown schedule held only once every four years and lasted six days,'' says Khazin. ''Repairs were implemented round-the-clock employing two works shifts. Specialised techniques like hydro-demolition of concrete to minimise the effect of vibration on the structure were utilised.

''The highlight of the activities was hydraulic jacking of existing vessels so that rehabilitation of the concrete foundations could be implemented. The method entails transferring the loads of a vessel to a purposely-built temporary steel structure. The procedure was carefully and precisely done using special equipment - a hydraulic jack. The assembly has a capacity of 20 tonnes and consists of four jacks, hand pump, hydraulic oil manifold, monitor gauge and shutter valves.''

Among the projects Almabani completed last year are:

''As the Jeddah Municipality did not permit connection to the sewerage system, a sewage treatment plant was installed to treat the sewage water and convert it to irrigation water for landscaping use,'' says Khazin.

''The air-conditioning system is supported by a thermal energy storage (TES) system which helps in storing chilled water during the night to be used in the air-conditioning system during daytime and peak hours.''

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)