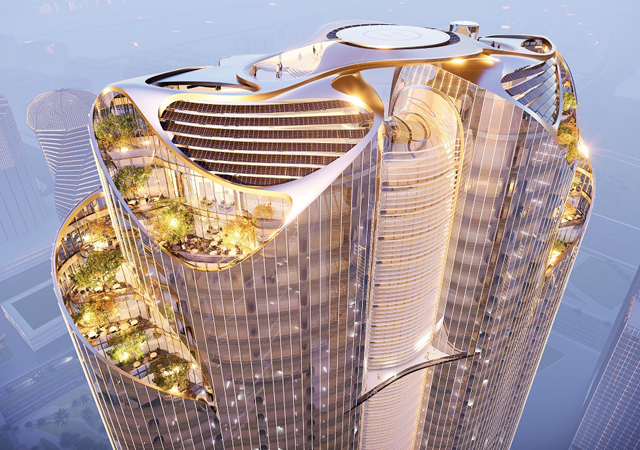

Thermoset’s panel tank manufacturing unit.

Thermoset’s panel tank manufacturing unit.

UAE-based Dubai Investments will field two leading players in their respective fields at the Big 5 as regular participant Thermoset Technologies Middle East (TTME) teams up with debutant Emirates Thermostone to put on an impressive stand at the event.

Thermoset Technologies, a specialist in state-of-the-art water storage systems, returns to the show after a successful innings last year and will showcase a sample hot pressed glass reinforced plastic (GRP) panel tank to demonstrate to potential customers the special features of this product. Sister concern Emirates Thermostone will promote its autoclaved aerated concrete (AAC) products, which are designed to meet today’s market demands.

Both firms are subsidiaries of M’sharie, which in turn is a wholly-owned subsidiary of Dubai Investments.

Established last year, TTME specialises in the manufacture of hot pressed GRP panel tanks, which use 30 per cent glass and UV (ultraviolet) stabilised PMC (polymer-matrix composite) material.

“They are claimed to be the safest and most durable tanks for use in the transportation of clean potable water across the Middle East and other countries,” says Obaid Al Salami, chairman.

“Our panels, designed with optimum engineered precision and a high-performance finish, are manufactured through the hot press moulding process, under strict quality control, using the highest quality materials and moulded under extremely high pressures at a temperature of 150 deg C. The production process is administered through the technical assistance of Thermoset Technologies UK – a global pioneer in glassfibre composite technology with wide experience in manufacturing various composite products in Europe,” he says.

The result is a strong, consistent, fully cured panel with a smooth surface finish design on both sides, optimising the benefits of a high-strung GRP matrix, which enables a tank of any desired size and shape to be constructed, he adds.

“Thermoset panel tanks are manufactured from non-corrosive material and consequently require little or no specific maintenance. The basic tank construction comprises GRP panels bolted together to form the tank size required. The inner surface of these panels in contact with the contents has a high gloss, smooth finish, which does not readily attract or retain dirt,” Al Salami explains.

Thermoset, a medium-sized company, aims to be a top-class hot pressed GRP panel tanks manufacturer in the region, capable of meeting industry demands for quality service, reliability and competitively-priced products, with a mission to succeed by effectively utilising advanced techniques, and providing good customer service. Over the past year, its team has worked hard to build its infrastructure to handle a high volume of business, while developing strong working relationships with its target customers primarily in the construction sector.

The company is now looking at appointing dealers/agents within the UAE and other GCC countries to distribute its products under its direct supervision.

Commenting on the market, Al Salami says: “The demand for glass fibres in the Middle East has grown at a fast pace in the past decade. In the next five years, both production and demand will continue to grow. One of the most important aspects that TTME will focus on in the year ahead is the development of additional GRP products. We have plans to manufacture new water-related products such as shower trays, bathtubs, kitchen sinks, electrical enclosures and washbasins.”

Emirates Thermostone

Meanwhile, Emirates Thermostone, which is based in Dubai Investments Park, is working on adding a second production line for AAC products to meet the demand of the growing markets of the Middle East.

AAC products are popular in construction due to their environmentally friendliness, weather, fire and pest resistance, easy workability and thermal insulative properties.

“AAC is essentially concrete with closed air pockets in it. It is lightweight and energy efficient, and produced by adding a foaming agent to concrete in a mould, then wire cutting blocks or panels from the resulting ‘cake’, and ‘cooking’ it with steam (autoclaving),” explains Ali Abdulkarim, general manager of the company.

“AAC blocks are popular in building construction due to their affordability and the fact that they can reduce the total cost of a project. They are economical to ship and handle and install easily without special crews or equipment. Prefabrication and quick erection shortens construction time, reducing construction and financing costs. AAC’s durability, fire resistance, and energy efficiency may reduce property-insurance premiums and operating expenses, contributing to the product’s life-cycle value,” he adds.

Emirates Thermostone was established in 2004 in a bid to provide high-quality building materials to the construction industry, he says. Since then, it has gained a reputation in the region for manufacturing quality heat-insulated aerated concrete of all types and sizes, using the latest global technologies.

“We have a well-planned growth strategy in place which includes establishing plant for the production of reinforced and non-reinforced AAC of all types and sizes, backed by a research and development programme to develop a product range that is constantly updated to reflect the changing demands of building industry. The company also aims to offer a dedicated technical service that will give advice on applications of suitability of AAC products to specifiers and house builders, while acquiring and partnering with other companies that carry out similar activities to achieve our goals for robust growth in UAE and abroad through greater diversification of revenue sources,” adds Abdulkarim.

Emirates Thermostone has a wide and varied clientele that includes various civil contractors across the Middle East and offers reliability, high quality production, short delivery times and personalised professional services.

.jpg)

.jpg)

.jpg)

.jpg)

Doka.jpg)